Browse other blogs

TaskMapper: Streamline Mechanical Activities During Solar Construction

A look at key mechanical activities in solar energy project construction, including installing mounting structures that house PV panels, and how TaskMapper simplifies monitoring, updates, and reporting for EPC contractors.

Overview of Mechanical Activities

In solar project construction, mechanical and electrical tasks are crucial for connecting PV panels to inverters, substations, and the grid. Effective task management and transparency are essential for successful execution and reporting.

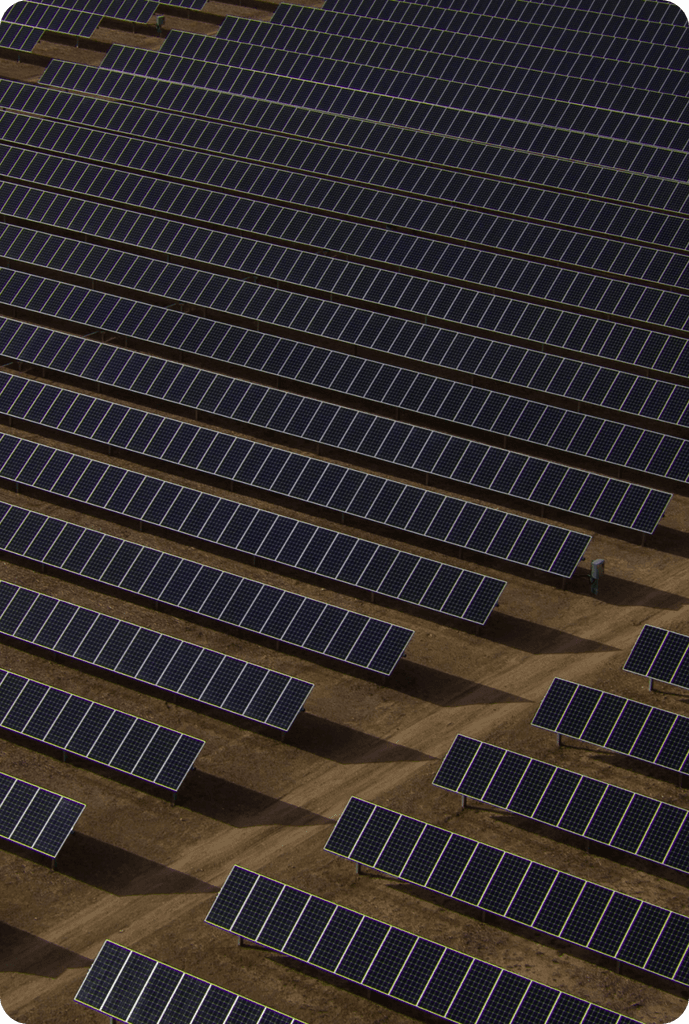

Mechanical work involves installing mounting structures that house PV panels for the life of the project. The different types of mounting structures include:

Fixed-Tilt Mounting System

This system features a fixed tilt angle, usually oriented East-West. It is the simplest and most cost-effective panel mounting option.

Pros: Low initial cost, easy installation, ideal for large, open spaces with minimal shading concerns

Cons: Less efficient than tracking systems, does not adjust for the sun's movement, potentially reducing energy production

Installation Process: The installation process begins with site preparation, where the site is cleared and leveled, and concrete foundations are used if the soil is unstable. Piles are then marked, staged, and installed with precision, with alignment being checked for quality. Following this, rafters and purlins are installed to create the framework. Modules are mounted and secured either manually or with cranes.

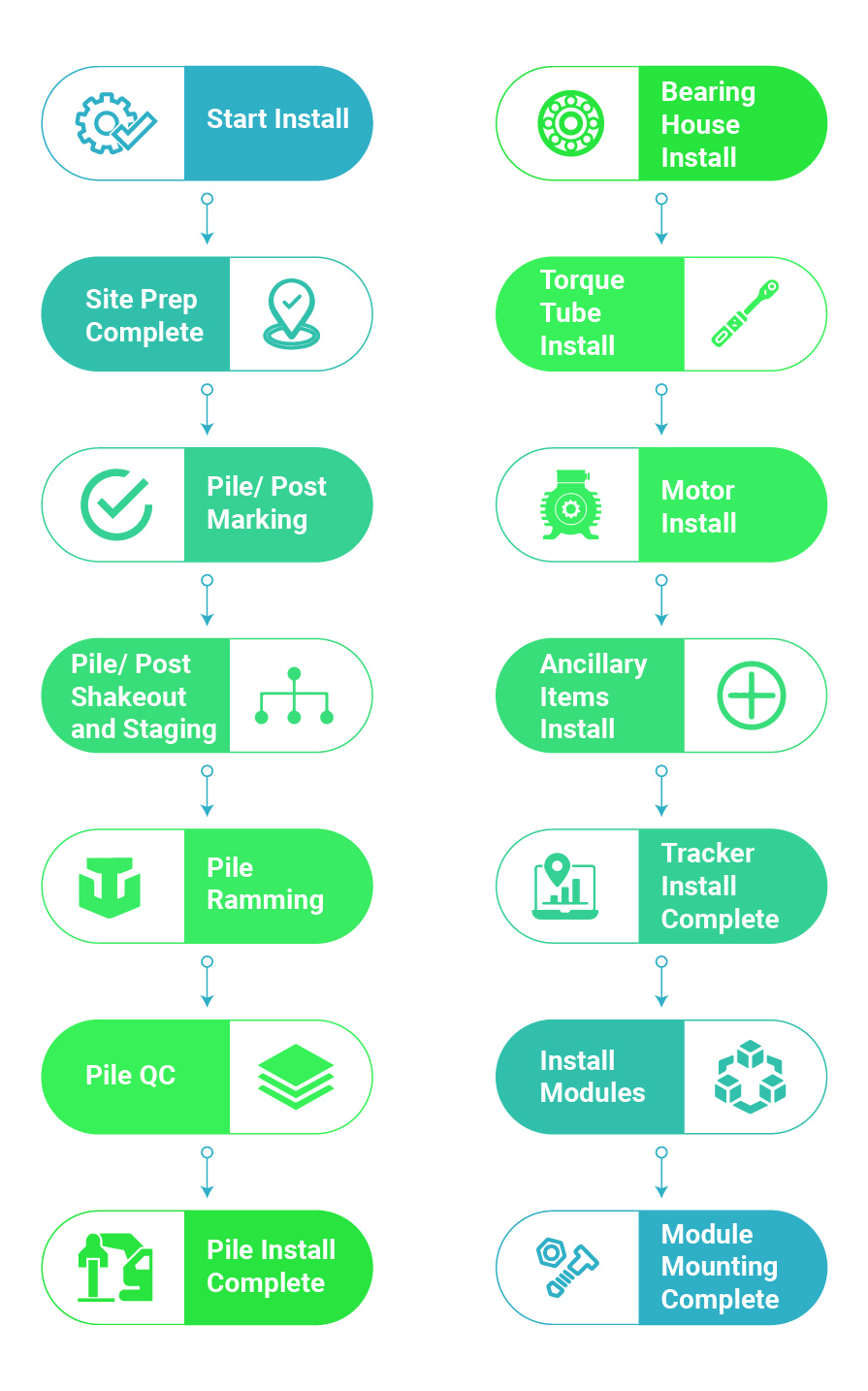

Single-Axis Tracker

This system allows solar panels to rotate on a horizontal axis to follow the path of the sun, enhancing energy production.

Pros: Increased energy yield compared to fixed-tilt systems, effective in locations with significant seasonal variations in sun angles

Cons: Higher initial and maintenance costs, not suitable for windy or space-constrained locations

Installation Process: The site is prepared similarly to fixed-tilt systems, with additional considerations given to soil stability. Piles are accurately marked, staged, and installed, with quality checks performed to ensure proper installation. Bearing houses, torque tubes, motors, and ancillary components are then installed for the tracker system. Finally, modules are mounted and secured, with cranes used if necessary.

Dual-axis trackers are rarely utilized due to their high cost and complexity, making them a viable choice only when maximizing energy output is essential and justifies the extra expenses.

The primary trade-off between fixed-tilt and single-axis trackers lies in balancing higher yield against increased cost and complexity. In regions where labor and land acquisition costs are relatively low, fixed-tilt structures are preferred. To compensate for the lower efficiency of fixed-tilt structures, the DC capacity of the plant is usually oversized compared to its tracker counterparts. Typically, the DC to AC Wp ratio is 1.2x for fixed-tilt projects but might go as high as 1.4x.

Understanding these systems and their installation processes enables better management of the mechanical aspects of solar project construction, ensuring efficiency and effectiveness in achieving project goals.

How TaskMapper Enhances Mechanical Activity Management in Solar Projects

Managing mechanical activities during solar project construction involves complex tasks, from installing mounting structures to ensuring precise alignment and timely progress. TaskMapper is designed to streamline these processes, offering EPC contractors advanced tools for effective management. Here is how TaskMapper can transform mechanical construction oversight:

Real-Time Monitoring and Updates

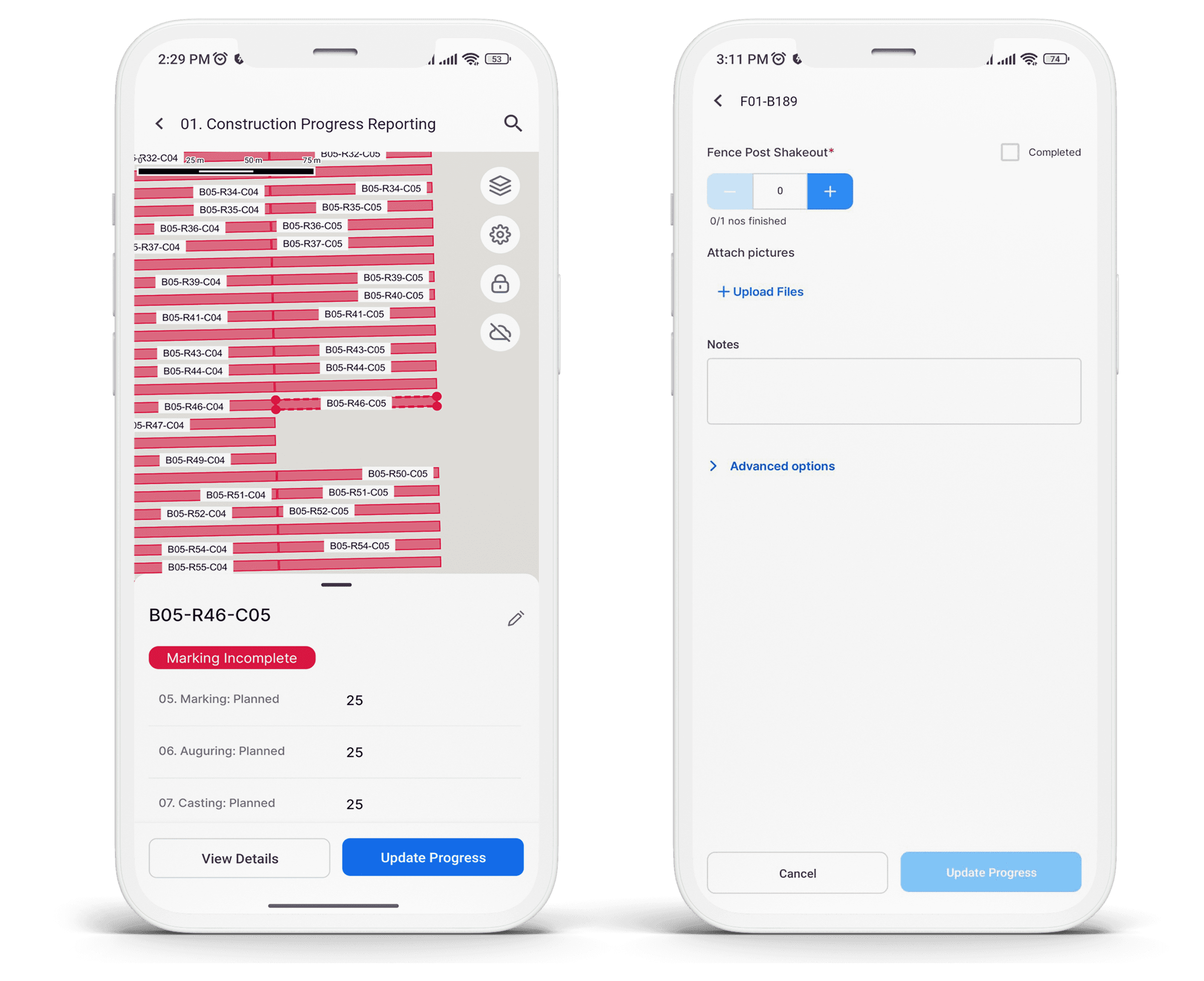

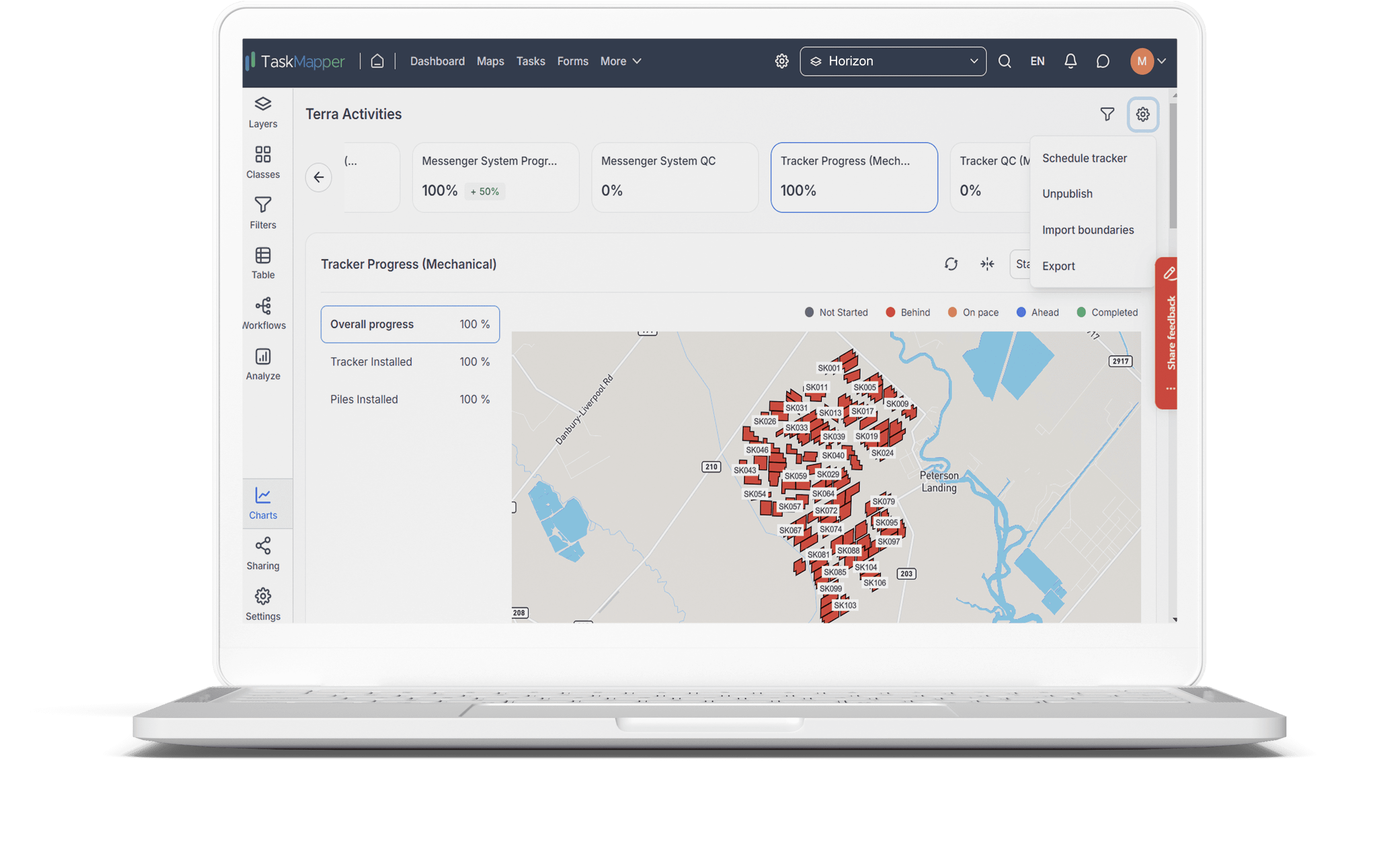

TaskMapper allows EPC contractors to efficiently monitor and update mechanical activities using mobile devices. This feature supports daily progress reporting for tracker and fixed-tilt structures, making it easier to keep track of project milestones.

Mobile app with tracker and fixed-tilt progress updates

Integrated Progress Databases

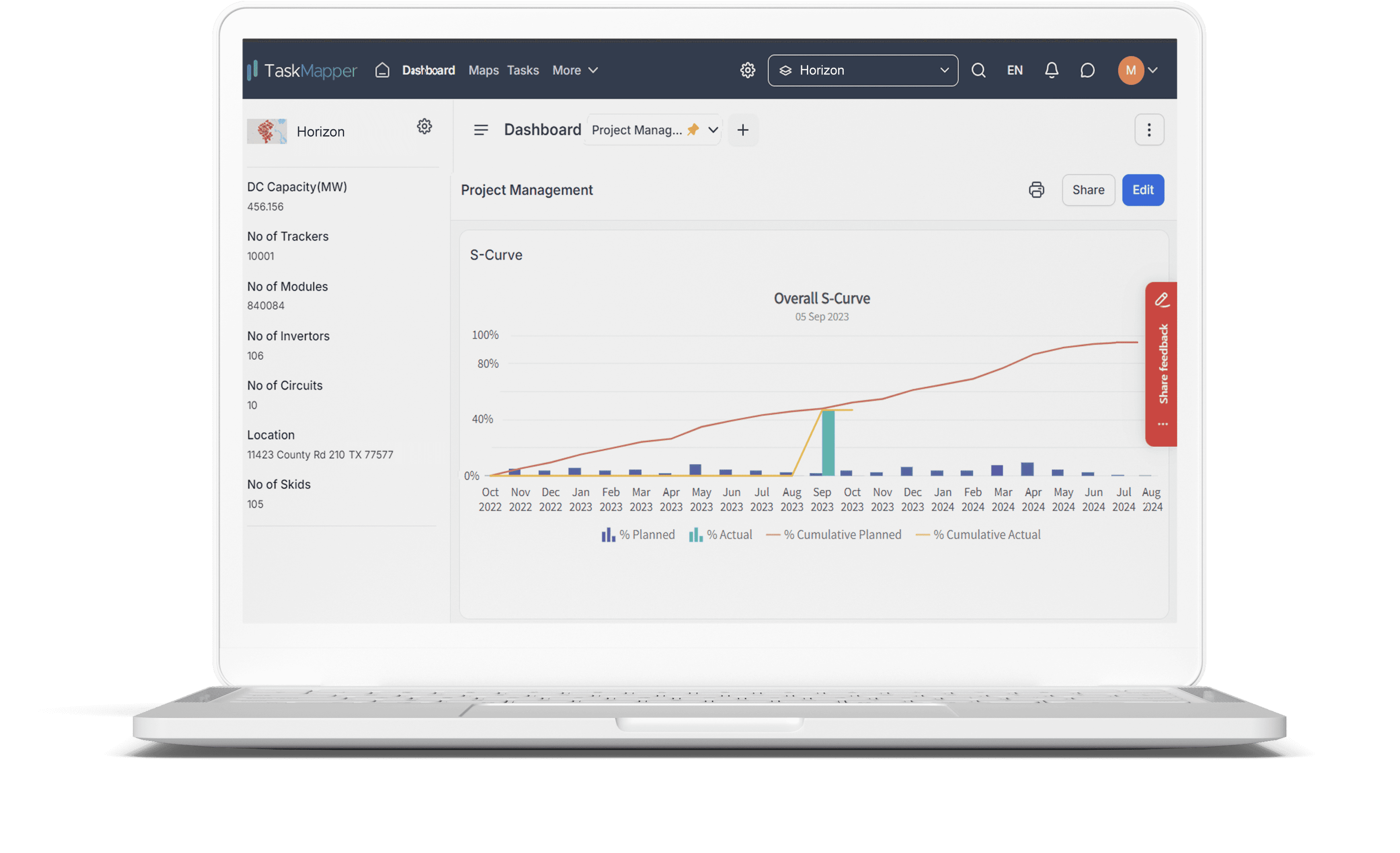

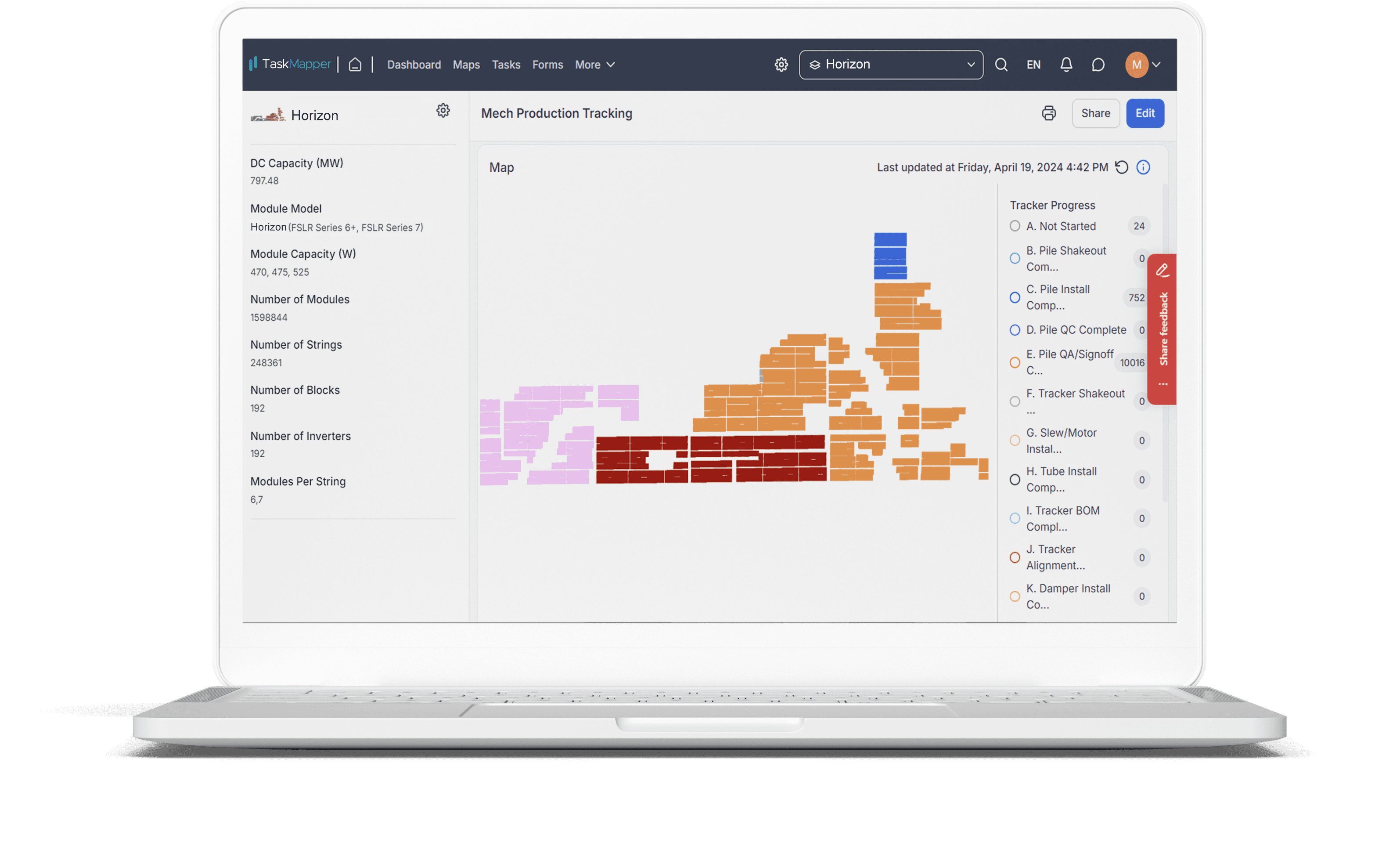

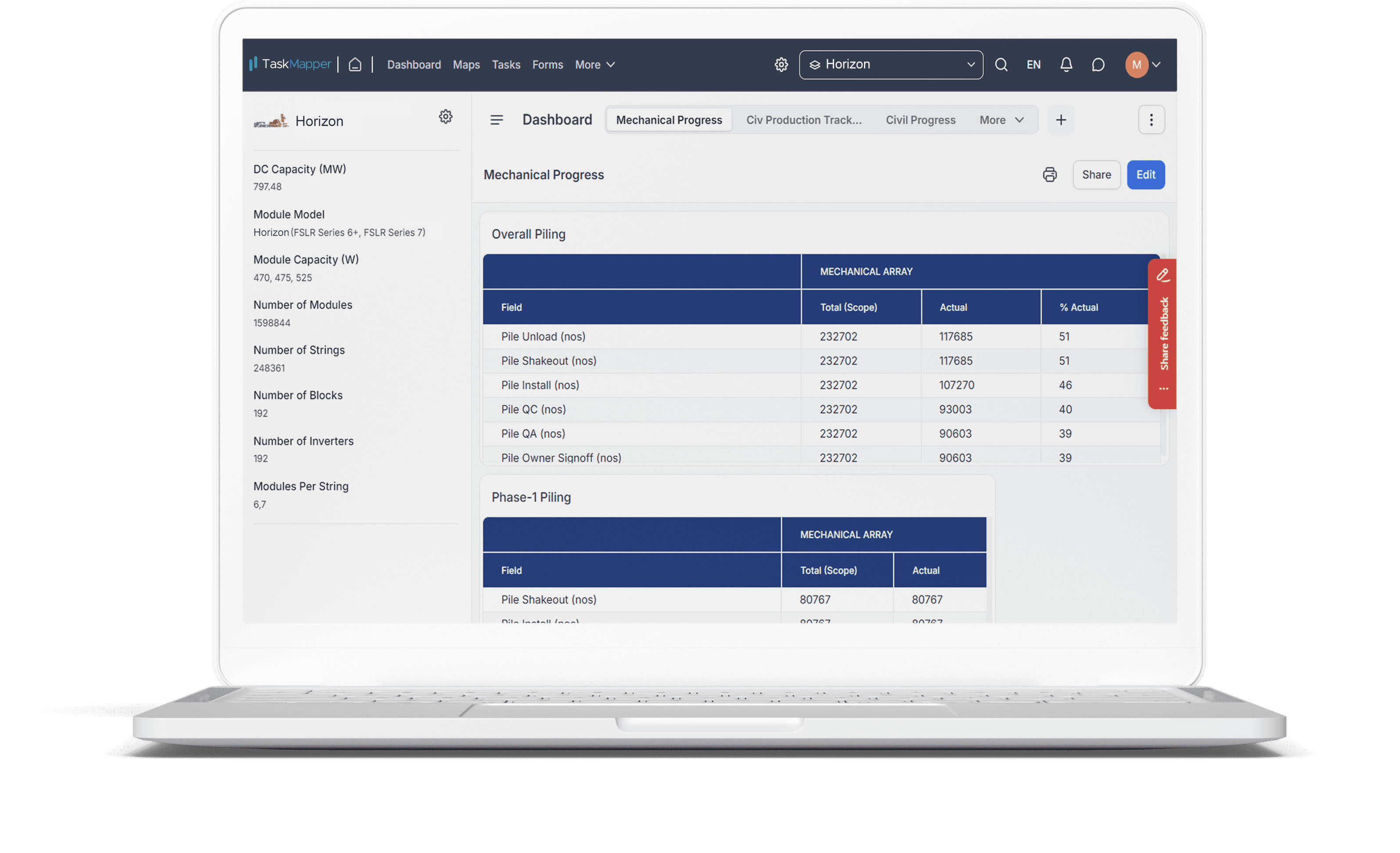

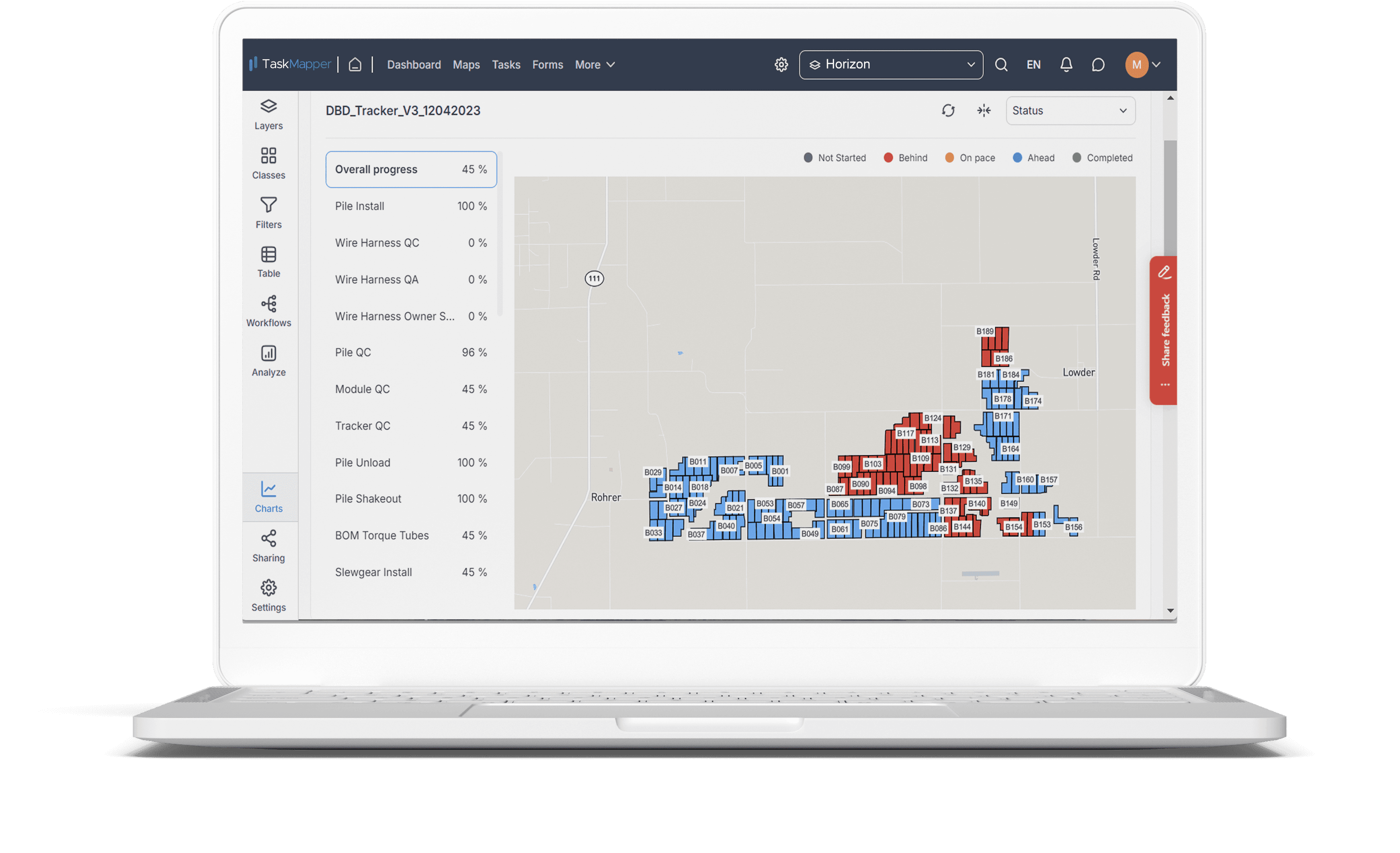

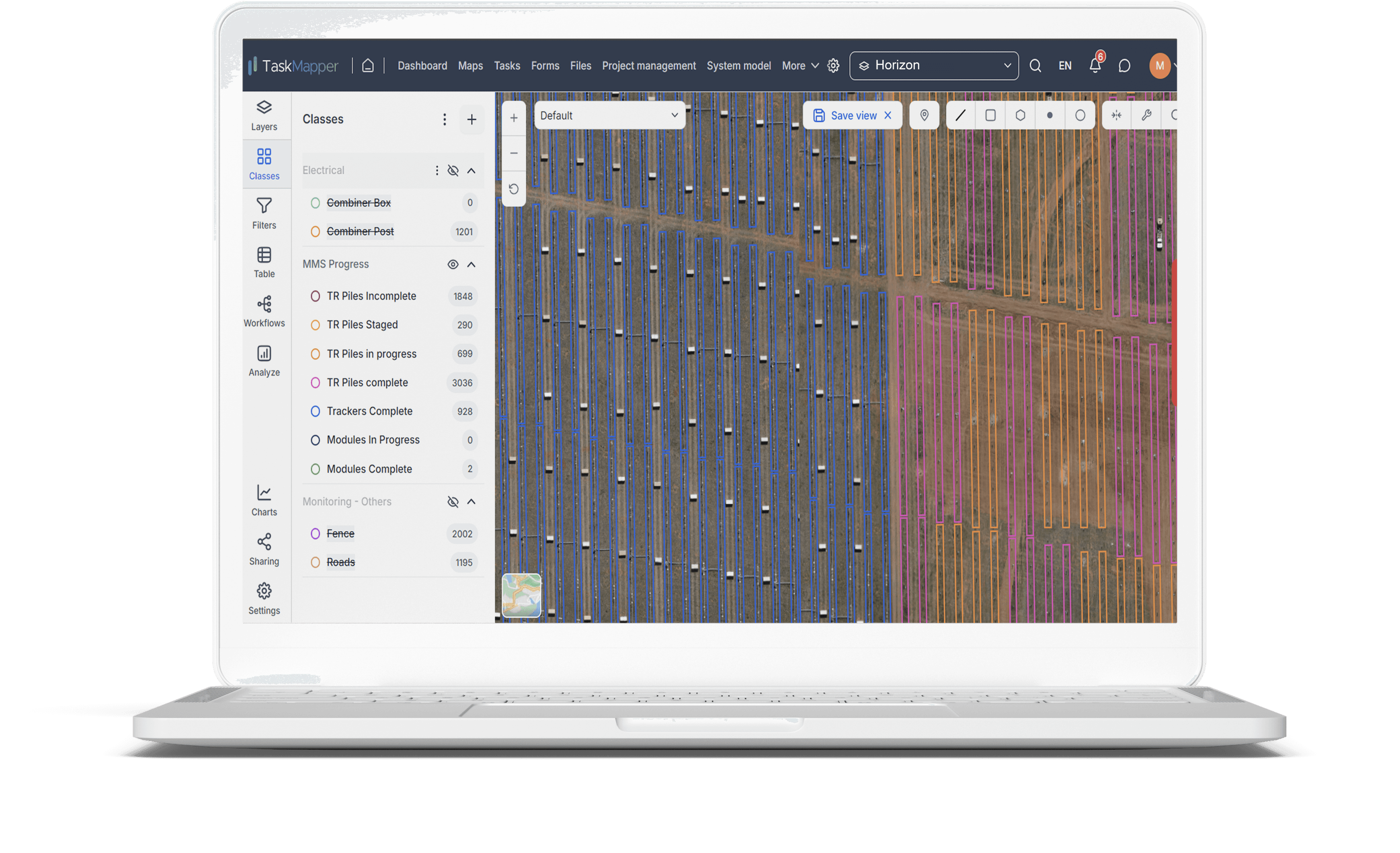

All progress updates are seamlessly integrated into TaskMapper’s construction databases, which offer both map-based and tabular views. This dual approach provides comprehensive visibility into the status of mechanical activities, ensuring that all stakeholders have access to real-time data.

Map view showing mechanical progress updates

Configure dashboard for quick view of mechanical work progress

Dashboard with S-curve updates

Project Schedule Synchronization

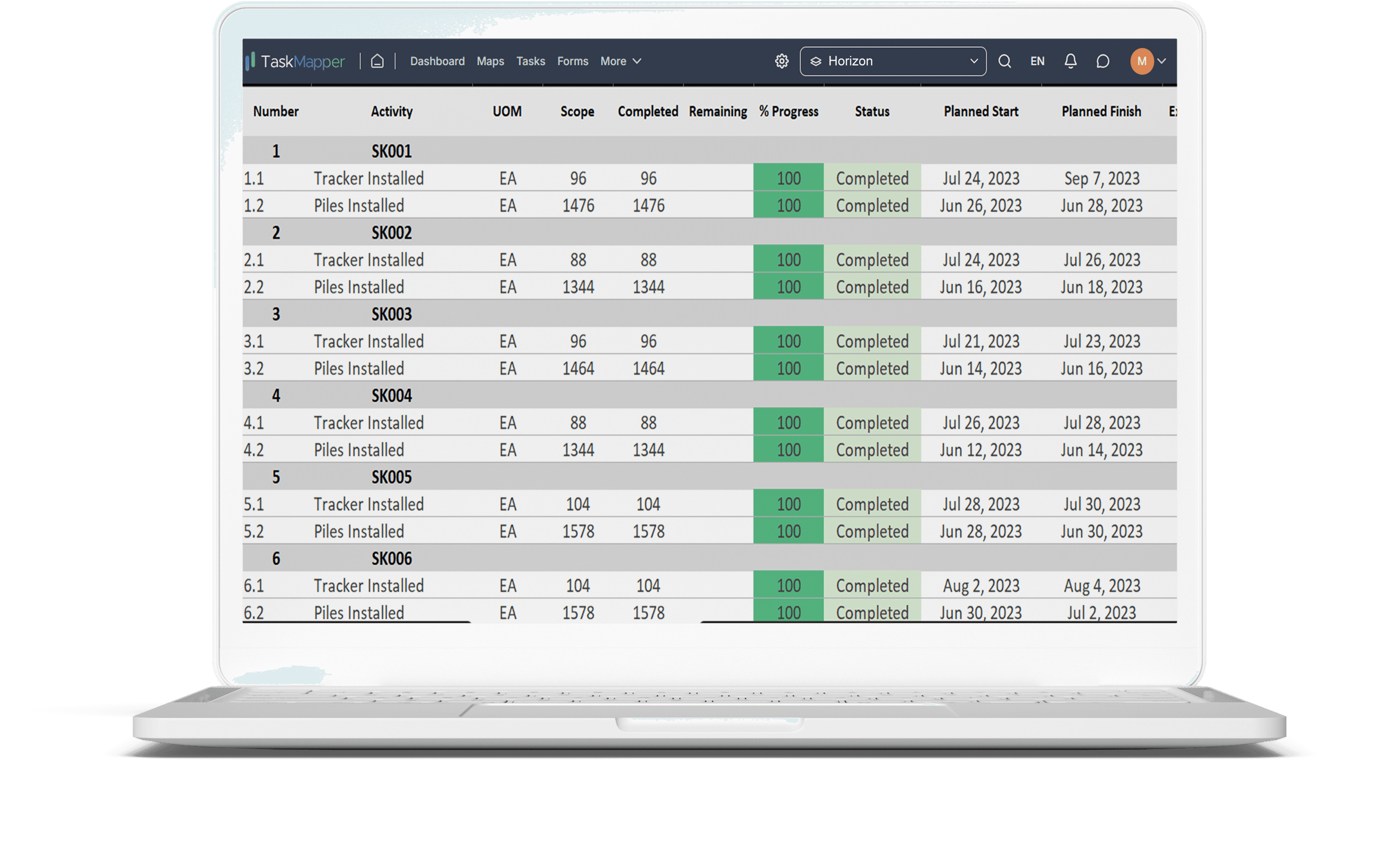

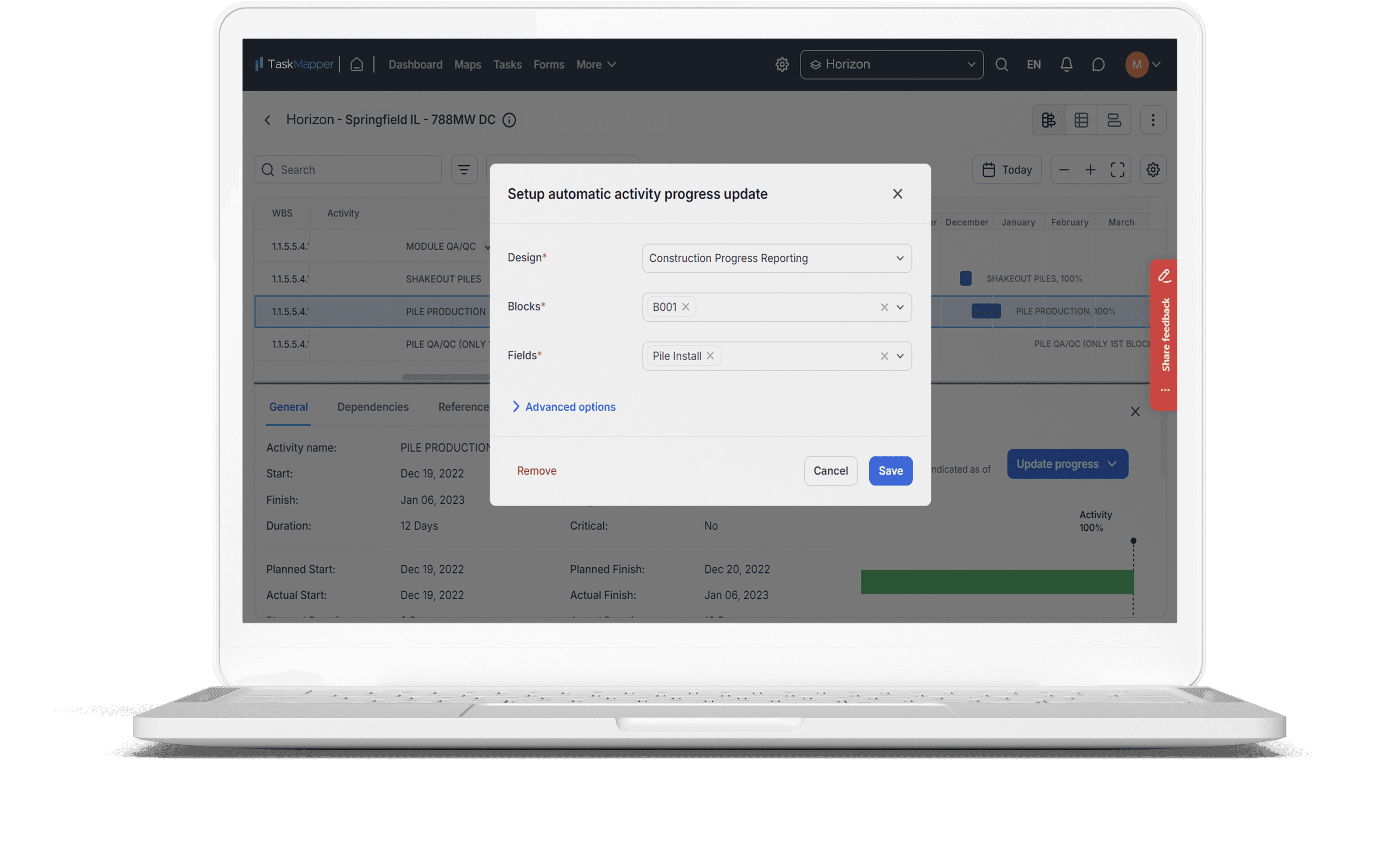

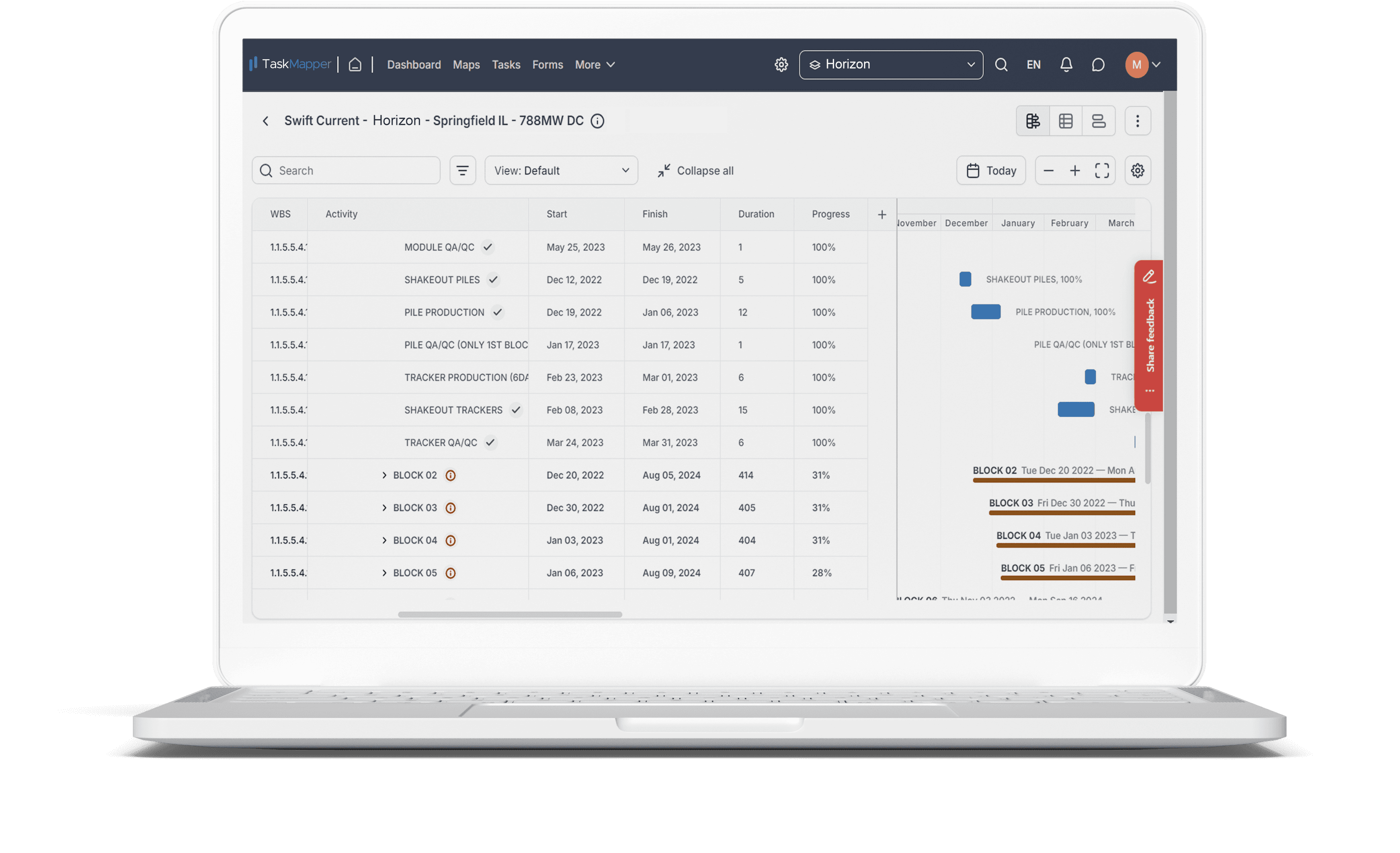

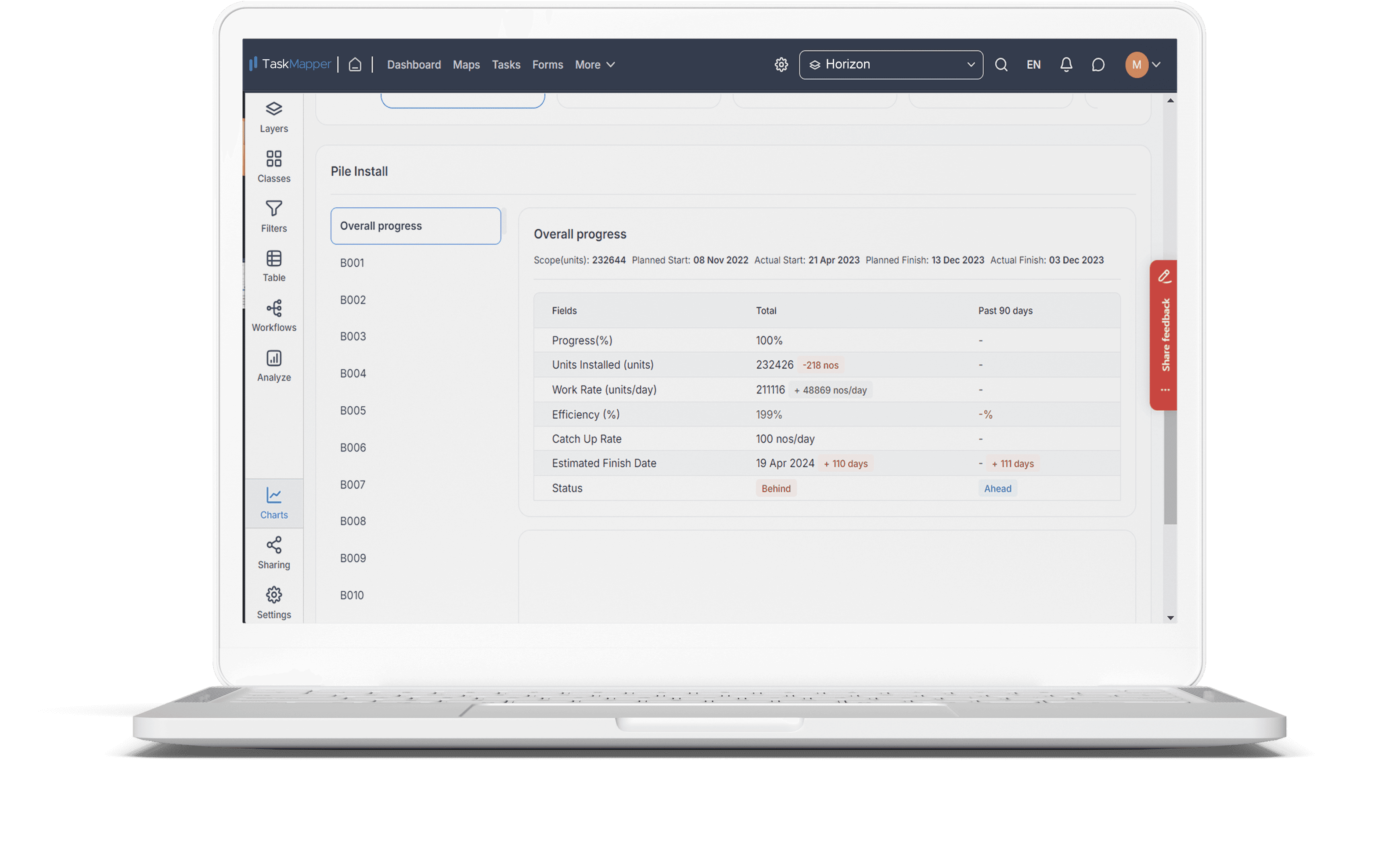

TaskMapper’s Project Management module allows EPC project schedules to be uploaded and synchronized. Civil activities within these schedules are automatically updated based on daily progress reports, ensuring accurate tracking and alignment with project timelines.

Schedule configured to auto-update mechanical progress

Updated schedule for mechanical activities

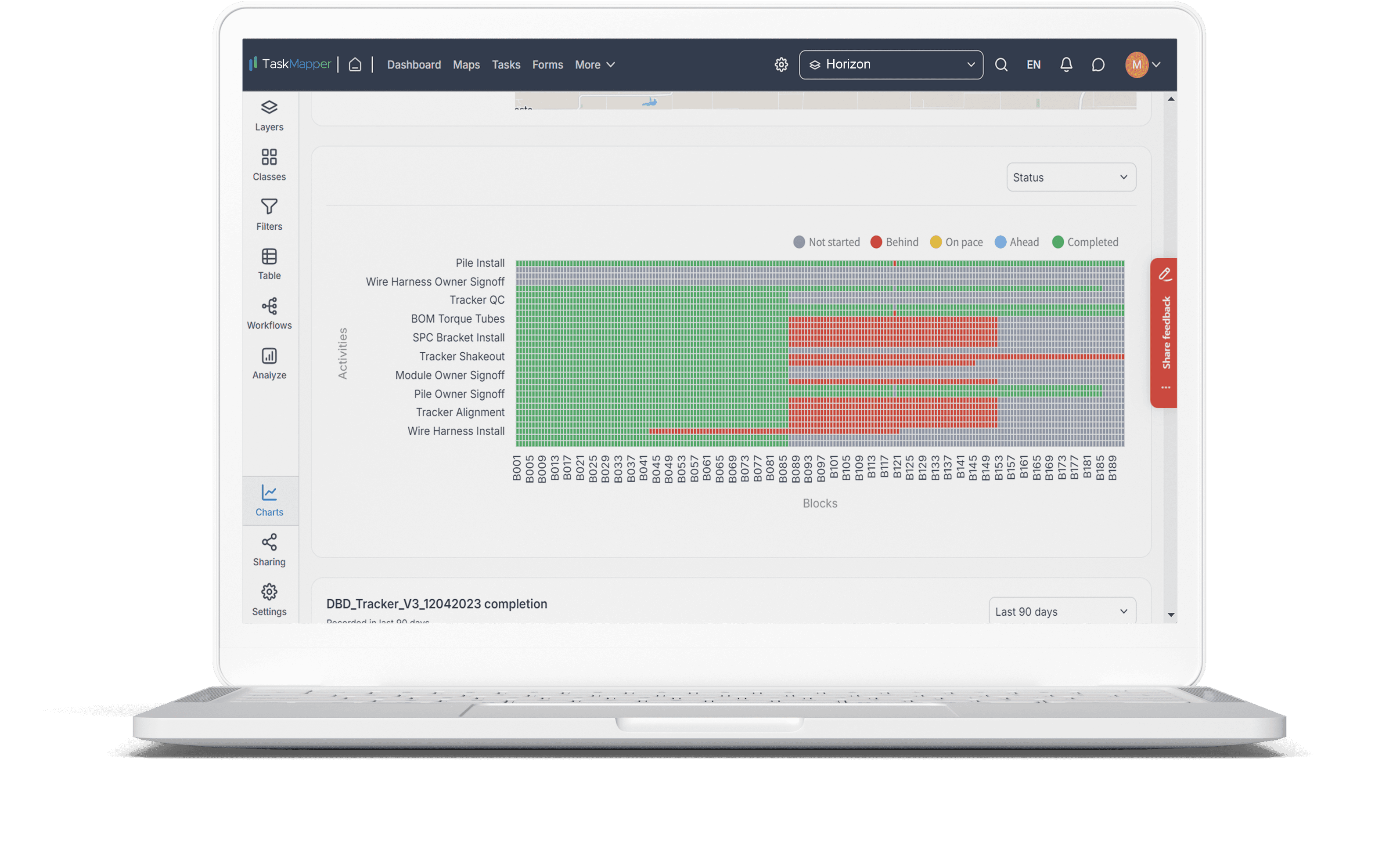

Map charts to track work progress

Progress graph for mechanical activities

Map charts to track work rate, catch-up rate, and more

Exportable Daily Progress Reports

TaskMapper simplifies reporting by allowing users to export progress data to Excel. This feature enables the generation of detailed Daily Progress Reports (DPRs), making documentation and review efficient and straightforward.

Progress report export option for easy sharing

Excel file for daily progress reporting

Drone Mapping for Field Audits

Drone mapping provides accurate field audits, validating manual updates and ensuring precise tracking of construction progress. This technology is particularly useful for verifying the installation and condition of mechanical components.

Drone maps displaying mechanical progress

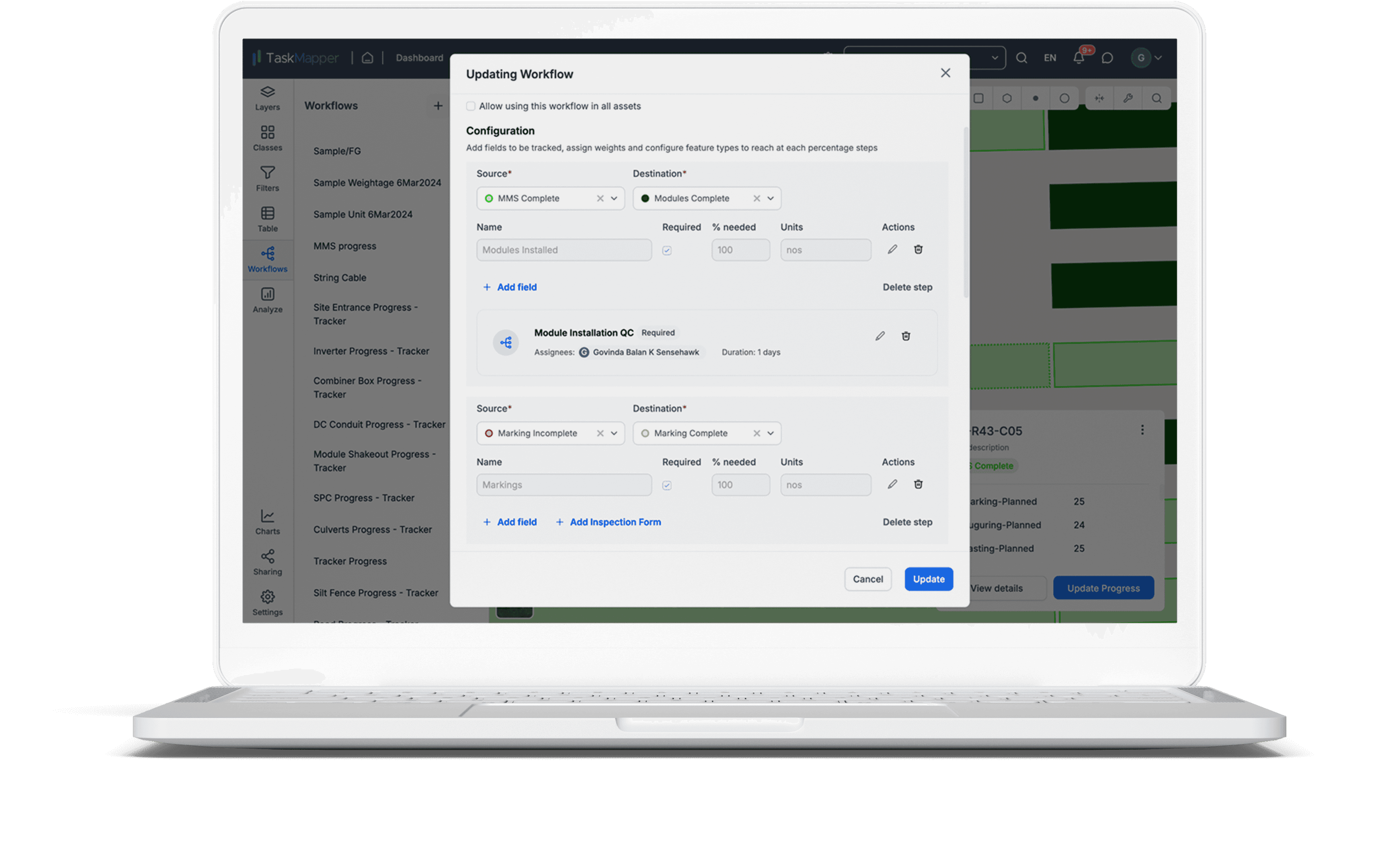

Automated QC Workflows

TaskMapper’s QC tools automate the quality control steps necessary for mechanical progress, especially at critical stages like piling. The system ensures that XYZ tolerances are meticulously checked and maintained, using automated workflows and QC forms.

Excel file for daily progress reporting

TaskMapper's advanced features streamline mechanical activity management, enhance accuracy, and improve overall project efficiency. By integrating real-time updates, automated scheduling, and detailed reporting, TaskMapper helps EPC contractors stay on top of their solar project construction tasks effectively.

This article is part of a series on how TaskMapper enables solar EPCs to improve project outcomes through digitization, automation, and real-time data integration. From preconstruction, civil, mechanical, and electrical activities to drone-based progress monitoring, inventory management, document control, and commissioning, TaskMapper helps boost efficiency and productivity and ensure projects are executed on time, within budget, and with guaranteed performance standards.