Browse other blogs

COMPANY

Main demo/ tutorial lorem ipsum dolor set amet

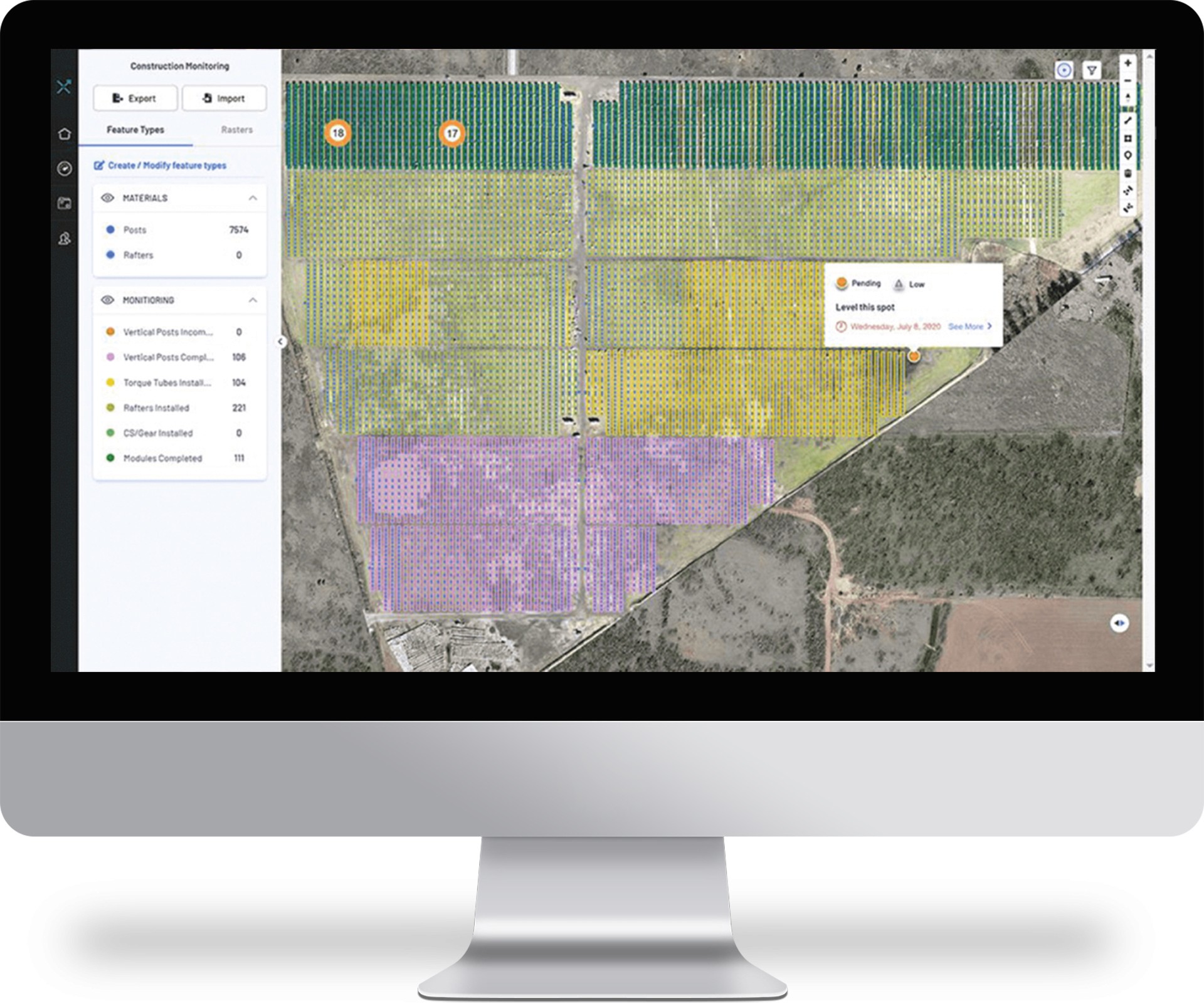

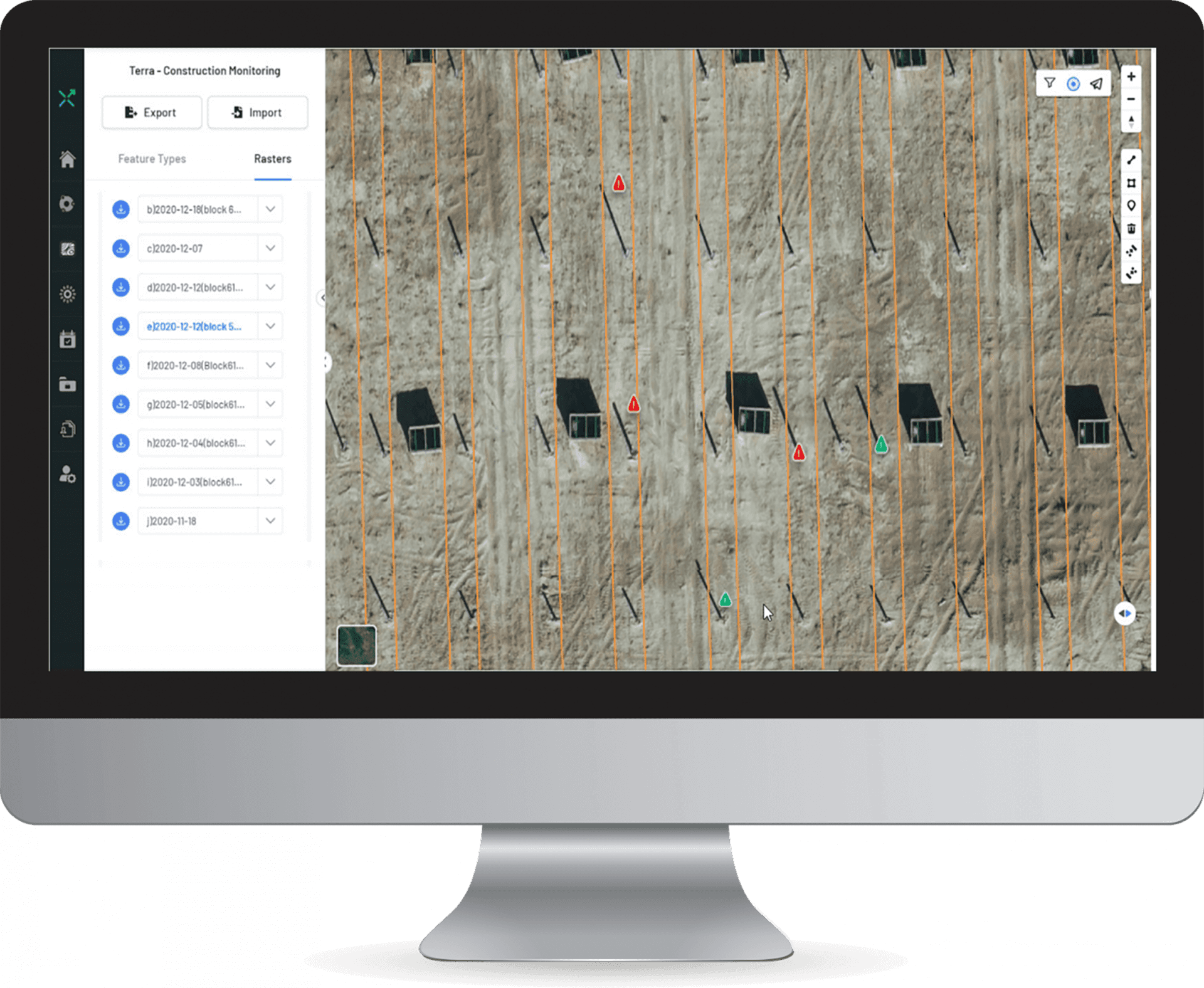

Figure 1: The digital twin of the solar power created on the SenseHawk SDP at the start of construction

Browse other blogs

digital-tools-for-solar-construction-in-the-post-covid-era

October 20, 2020

Digital tools for solar construction in the post COVID era

Team SenseHawk

Digital tools for solar construction in the post COVID era

Read more

Contact us

Abhijit Sathe

CO-CEO, SB Enegry

How the SenseHawk Solar Digitization Platform helped clients minimize the project-lifecycle related obstacles and associated risks that became apparent after the first 12 months of the pandemic.

The BUILD feature of the SenseHawk SDP enabled over 3GW of solar projects in the first 12 months of the COVID pandemic.

The BUILD capability of the SenseHawk SDP is a full-featured solar construction management system that integrates project scheduling, jobs assignment, onsite reporting, workflows, quality control, documentation, and stakeholder reporting.

In the first 12 months of the COVID-19 pandemic, BUILD was used in the construction management of over 3GW of solar projects. The prevailing mood among these customers, across different countries and continents, was the same: The Corona virus is impacting current and planned construction activities on utility-scale solar sites.

Industry participants listed work and site access restrictions as the biggest obstacle to post-pandemic recovery, with challenges that ranged from travel restrictions and social distancing requirements to the real and present danger of contracting or spreading COVID on a construction site.

Project managers were struggling to create new workflows that mitigated the challenges associated with COVID-19, while meeting already stretched deadlines and budgets caused by the knock-on effects of the severe lockdowns. All this, while reducing the number of boots (foremen/field managers and onsite technicians) on the ground to a minimum. The result, makings of a perfect storm as evinced by the situations faced by some of the customers:

Several tracker posts on your site have been drilled to incorrect depths. However, TAT on getting the drilling equipment back onsite is 2 months due to COVID backlog.

NCU controller cables have been incorrectly labeled for one of the inverters, resulting in unresponsive trackers. Fixing it requires significant electrical rework but you are already 2 weeks late for your hot commissioning deadline. Further, your team is operating at 50% capacity due to COVID and you are looking at stiff penalties for missing cliff dates.

How does a project manager adjust to a new reality, where there can be absolutely no mistakes on the field, and efficiency, at times, needs to go up by 100%?

STEP 1: Know exactly what is happening on site

This might sound simple enough – every project manager will want to trust the reports being turned in by their foremen and their subcontractors. In practice, however, the construction progress being reported on site is off by up to 20%. The problem is not one of malfeasance or carelessness – it is just humanly impossible to give an accurate update of installed numbers without an aerial view of the site. How do you fix this?

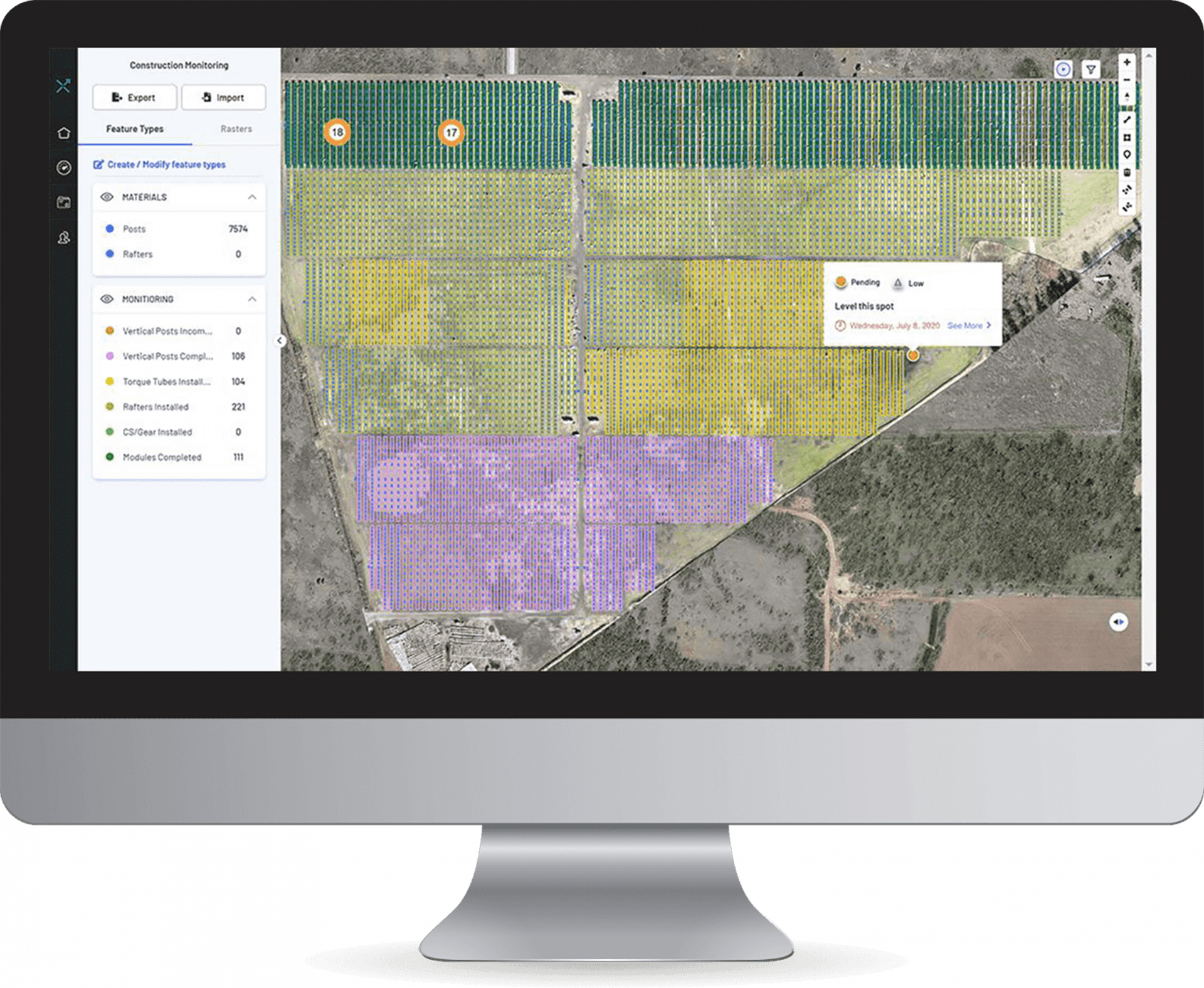

Below is the construction progress map of a solar powerplant, created using high-res drone imagery. An ML based algorithm accurately counts the number of installed components and classifies and color codes more complex installations based on the state of progress. The user can either view these reports online on a cloud-based app, or these reports may be exported to the user’s project management system, to reflect the on-ground reality accurately. Drone flights may be conducted once a week, or more frequently, to give an accurate representation of construction progress.

STEP 2: Identify issues, early

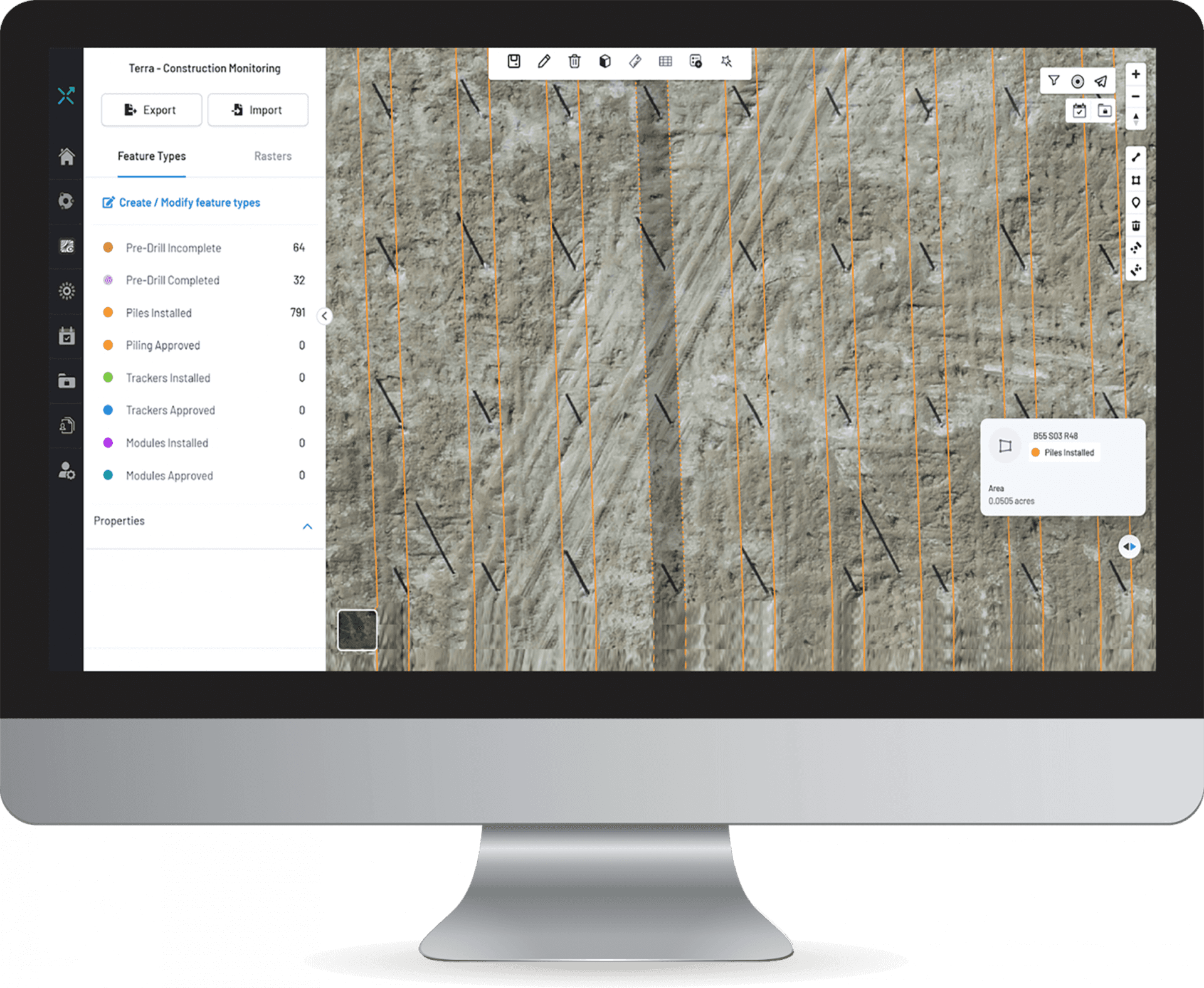

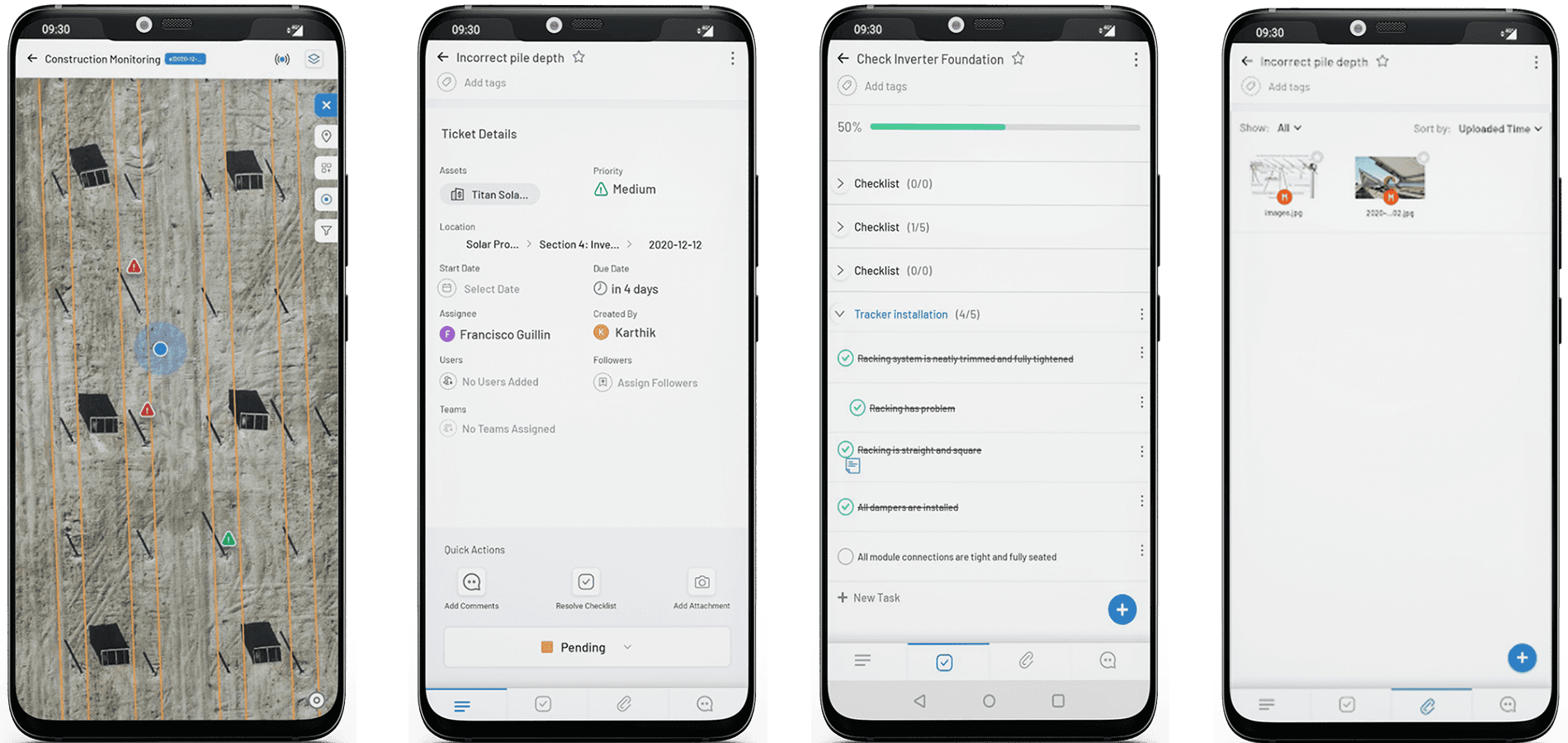

Remember the customer who realized that tracker posts were drilled to incorrect depths? They did not really face crippling delays in construction – they had a drone map available to check pile depths the same week that the piles were drilled, and corrective action was taken the very next week. They also had a digital twin of the site loaded onto the construction management platform – allowing users to identify exactly which component had quality issues, directly on the digital map view.

From the high-res map above, it is quite obvious that some piles have been driven to different depths than others. The customer was able to exactly locate the tracker posts that needed remediation. For instance, in the map above, tracker number S03 R48 in inverter Block 55 has been selected on the map and has Post number 5 drilled to an incorrect depth.

STEP 3: Communicate and remediate, NOT on email

Once the customer identified the faulty posts, remediation could have happened in two ways:

Send an excel list of faulty tracker posts to the field for remediation

Create a digital list of remediation tasks and checklists, individually assigned to team members, on an interactive map-based mobile application

No prizes for guessing which method was employed. The project manager bulk-created tasks for each faulty post, directly on the desktop app.

These tasks were individually assigned to field engineers. Field engineers logged in to the mobile application to navigate around the site, directly to the task locations.

Detailed checklists were assigned to each task. Field engineers checked off each checklist item and attached photographs of work progress to the task. The project manager could in turn attach PDFs and other reference files to the task on the desktop application in case help was needed on the field.

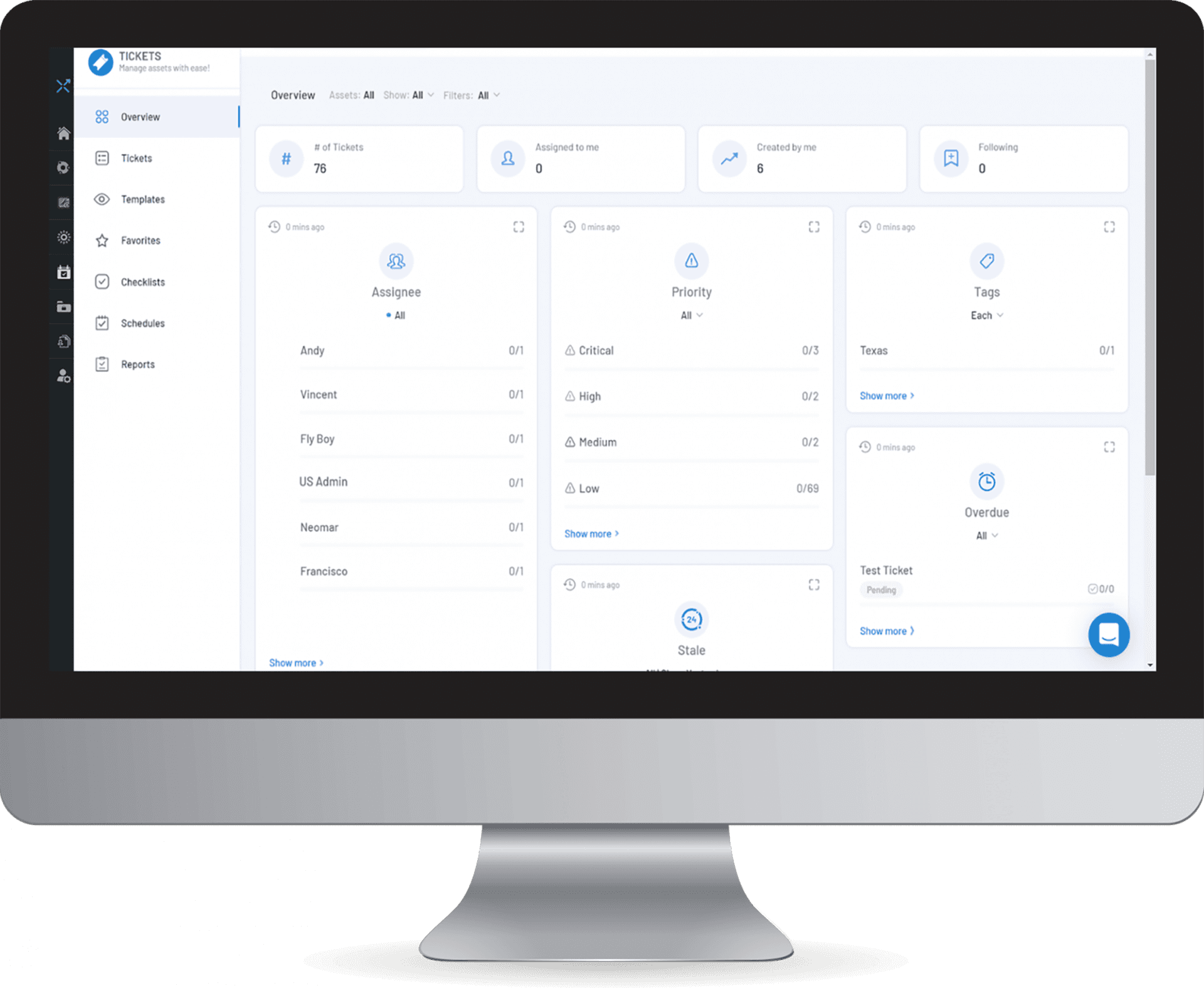

In this manner, a complex task that might have needed multiple rounds of checks and re-checks by the project manager, was converted into a collaborative effort, which required fewer emails and phone calls to organize. At the end of each day, the project manager could check work progress directly on a single reporting dashboard:

Customers have been using similar workflows for dealing with other routine and one-off construction tasks, including:

QA/ QC checks

Punchlist creation and remediation

Inventory checks using mobile bar-code scanning applications

Post-construction thermography (drone based and hand-held) and fault remediation

Post-construction shadow analysis

Using the SenseHawk SDP helped minimize COVID related risks across the project lifecycle. The examples quoted here show only a glimpse of what is possible with a completely digitized construction workflow.

To know how the SenseHawk SDP can help you manage your construction project better, book a demo at www.sensehawk.com/request-a-demo/

The EPC has also completed an important activity that will prove to be particularly useful for warranty claims. During the final stages of construction, serial numbers of every installed module had been captured and saved onto the digital twin on the SDP using the BUILD feature.