Browse other blogs

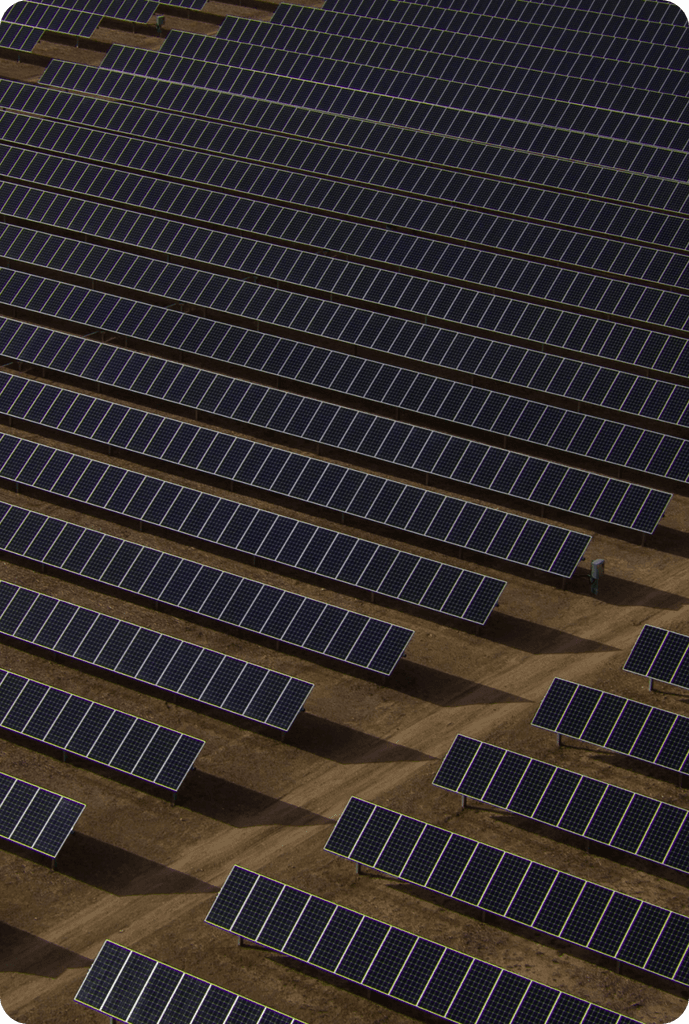

Digital Twins: Game-Changers in Solar Construction and Handover

In the solar PV sector, digital twins have predominantly been associated with operational assets and maintenance. However, digital twins can play an equally valuable role during the construction phase of solar assets.

A recent study by the Royal Institution of Chartered Surveyors (RICS) delves into the application of digital twins for construction and handover. Although primarily centered on the built environment, the report offers insights that are highly relevant to solar projects. Distilled here are some key points that apply to solar construction management.

Enhanced Data Management With Digital Twins

A digital twin is a virtual representation of a real-world entity and its processes. Synchronized at a specific frequency and fidelity, the digital twin consistently provides as-built and operational data. In solar construction, the digital twin encapsulates:

Interconnected digital assets like CAD files, images, point clouds, and documents that capture information about construction objects.

Component and system data with encoded hierarchy and insights into processes and work performance.

Digital twins enable seamless data collection, management, and utilization throughout the project lifecycle, from inception to decommissioning of solar assets. They act as a knowledge graph of the real-world entity, integrating data from various sources, including as-built or asset information models (AIM).

Digital twins consolidate all handover information into an easily accessible and updateable model for use during operation, maintenance, renewal, and end-of-life stages.

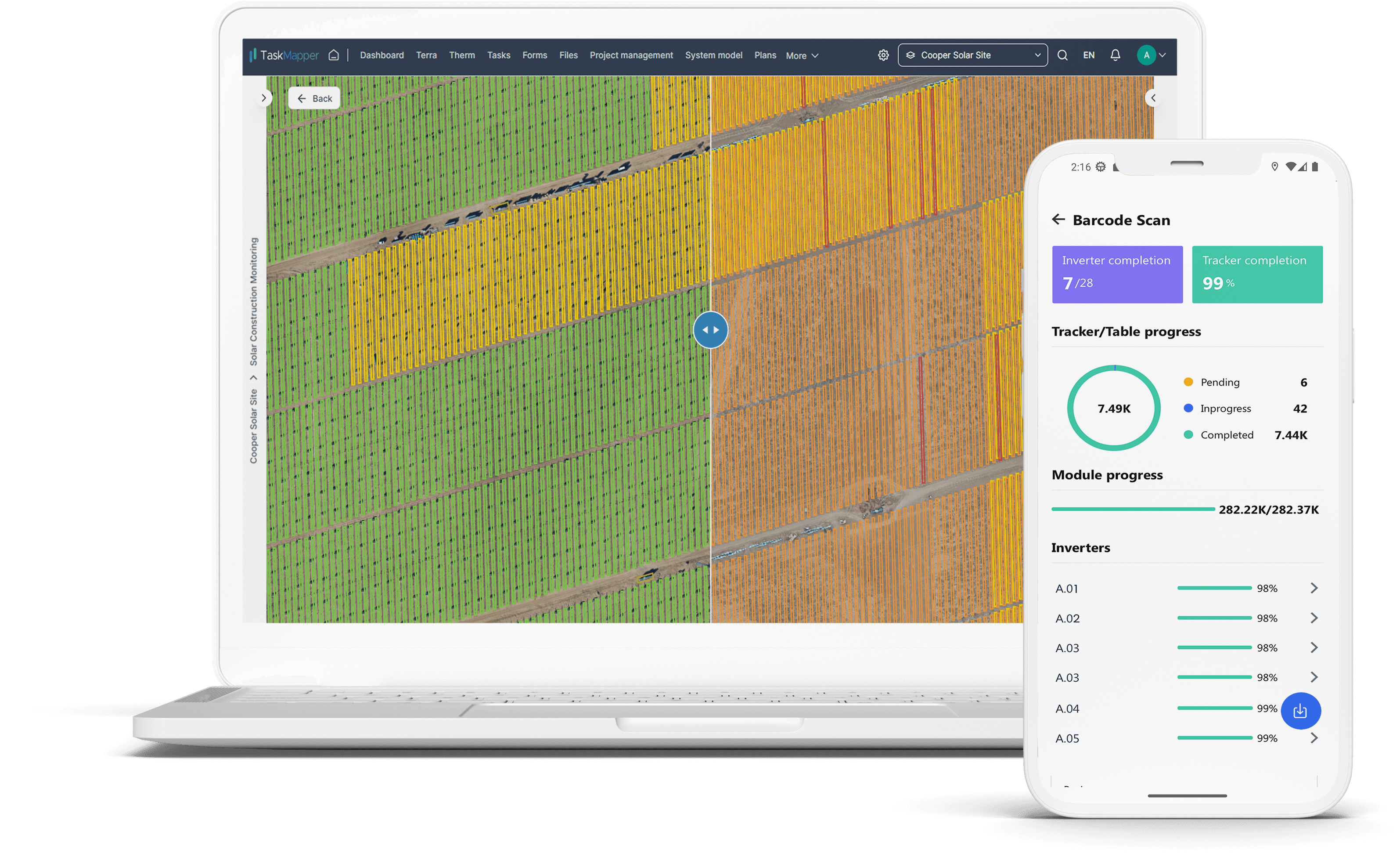

Barcode scanning of installed modules and roll-up reporting from the site help visualize construction activities and manage geolocated tasks and forms using digital twins.

Benefits of Using Digital Twins in Construction

Adopting digital twins in construction offers numerous advantages:

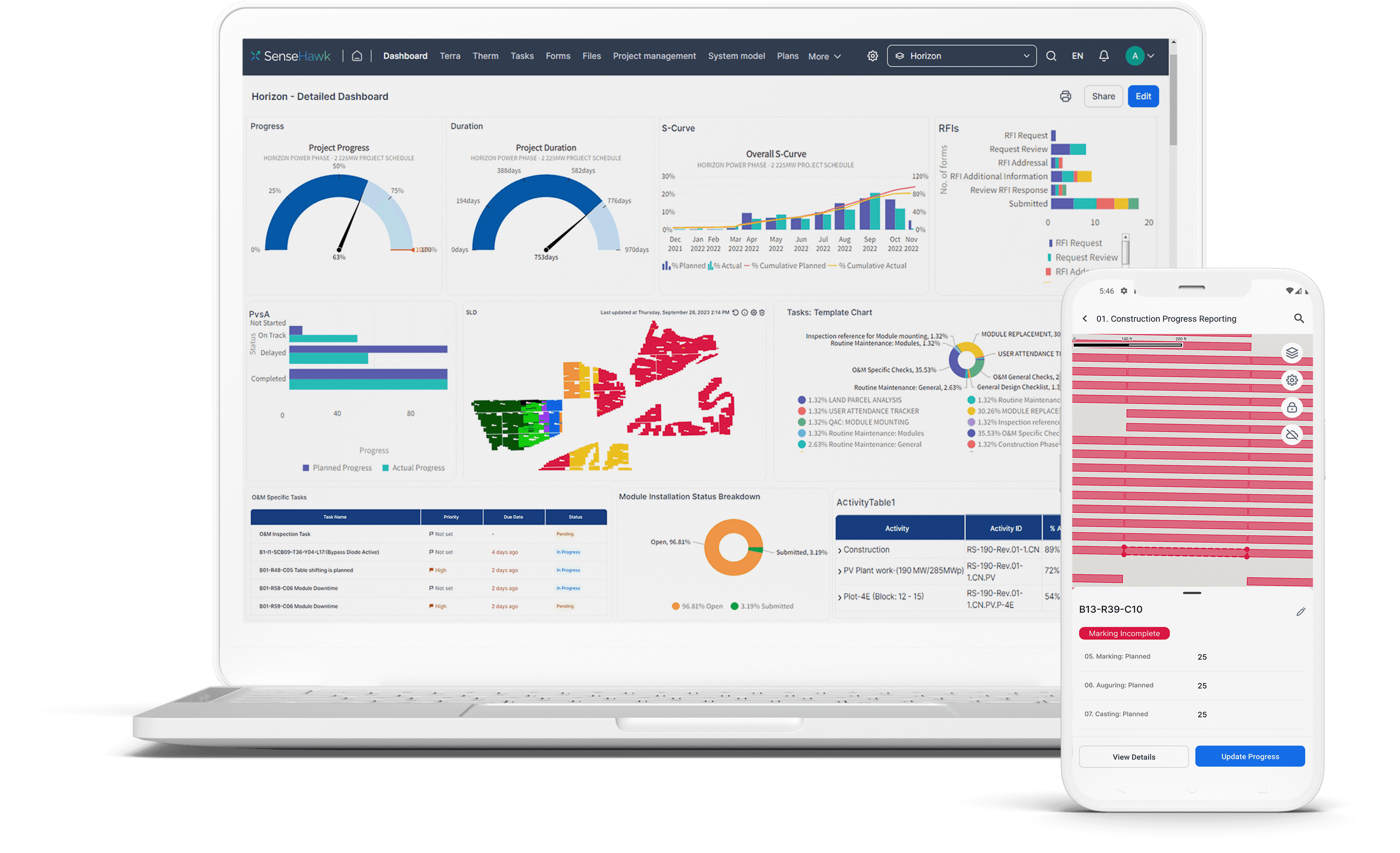

Streamlined progress reporting with better visualization and real-time dashboards to improve decision-making.

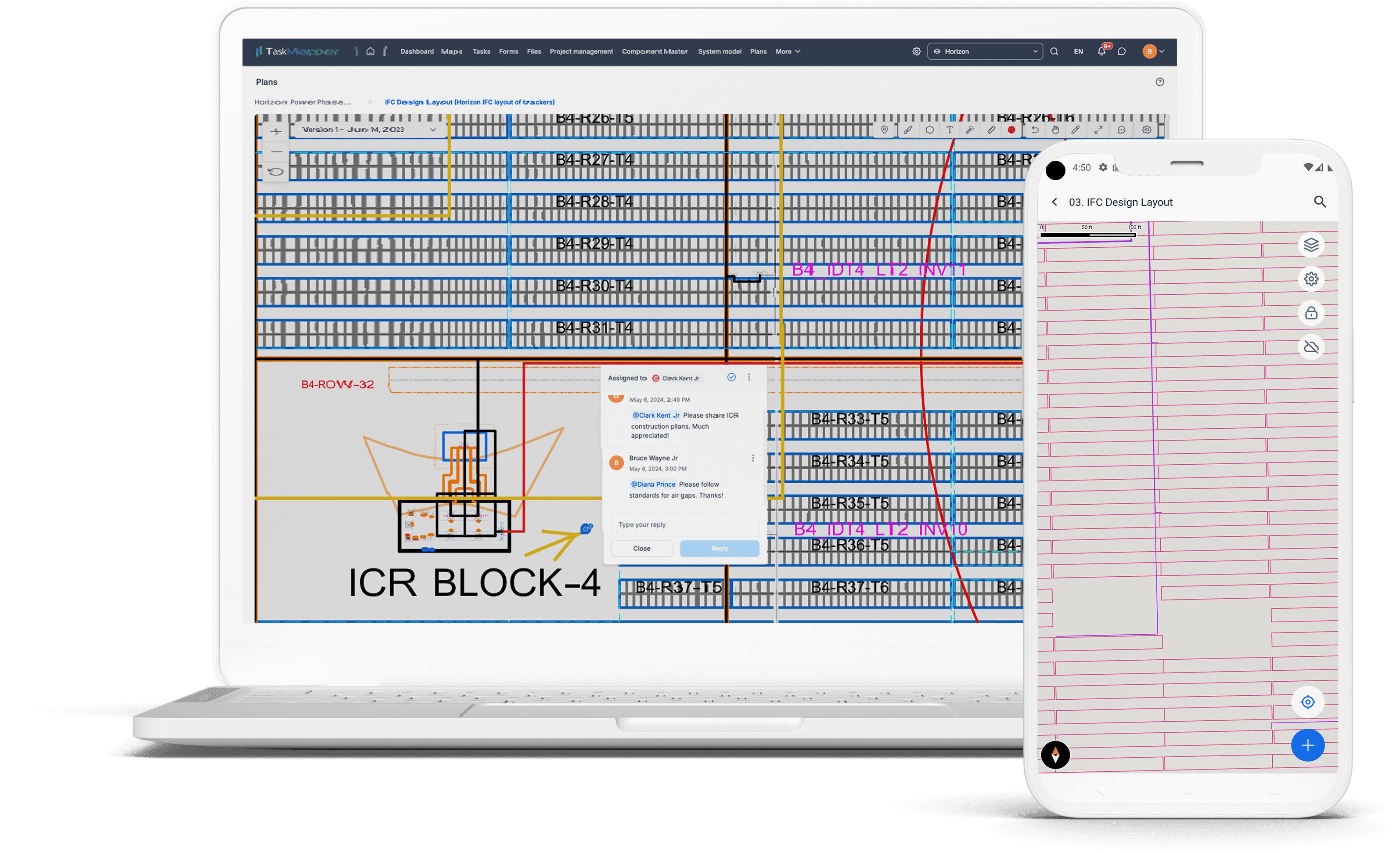

Enhanced collaboration among engineering, construction, quality, procurement, supply chain, and health, safety, and environment (HSE) teams using AIM-based processes to build better, faster, and safer.

Increased productivity and operational efficiency through easy “visual” access to critical information for on-site teams.

Improved efficiency in tracking and managing on-site materials and equipment.

Reduced errors, rework, and fragmented work practices, and hence lower costs, through real-time work performance data from the construction site.

Substantial time savings for site teams with automatic data compilation and reporting, allowing more time for actual site work.

Accelerated handover process by ensuring all data captured during construction, including images, videos, quality information, and component serial numbers, is available in a cohesive as-built model.

Stakeholder dashboards that automatically update based on progress updates from the field help simplify reporting.

Key Survey Insights from Construction and Project Management Professionals

The RICS online survey revealed the top three uses and deliverables of digital twins in construction, highlighting their pivotal role in enhancing performance efficiencies, supporting decision-making, and providing crucial project controls.

The top three uses for digital twins in construction:

Facilitating data sharing to improve performance efficiencies for all stakeholders

Gathering real-time site data for decision-making and collaboration

Progress monitoring and project controls

The top three deliverables for digital twins in construction:

As-built BIM-based models

Dashboards showing connected real-time asset data

Digital assets for various work processes

Digital twins are for more than just the operational side of solar projects. They can be game-changers during construction too, simplifying data management, easing reporting, and supercharging collaboration.

Organizational Capabilities Required for Implementing Digital Twins for Construction and Handover

Implementing digital twins for construction and handover requires certain organizational capabilities. A comprehensive information management framework is essential to handle the vast amount of data generated and utilized throughout the asset lifecycle. This framework must adeptly collect, structure, store, share, update, and utilize data effectively to support informed decision-making at every stage of the project.

The establishment of a formal mechanism is crucial to ensuring timely access to accurate and relevant information. This mechanism guarantees that the right data is available to the right stakeholders at the right time and maintains a high level of quality throughout the project lifecycle.

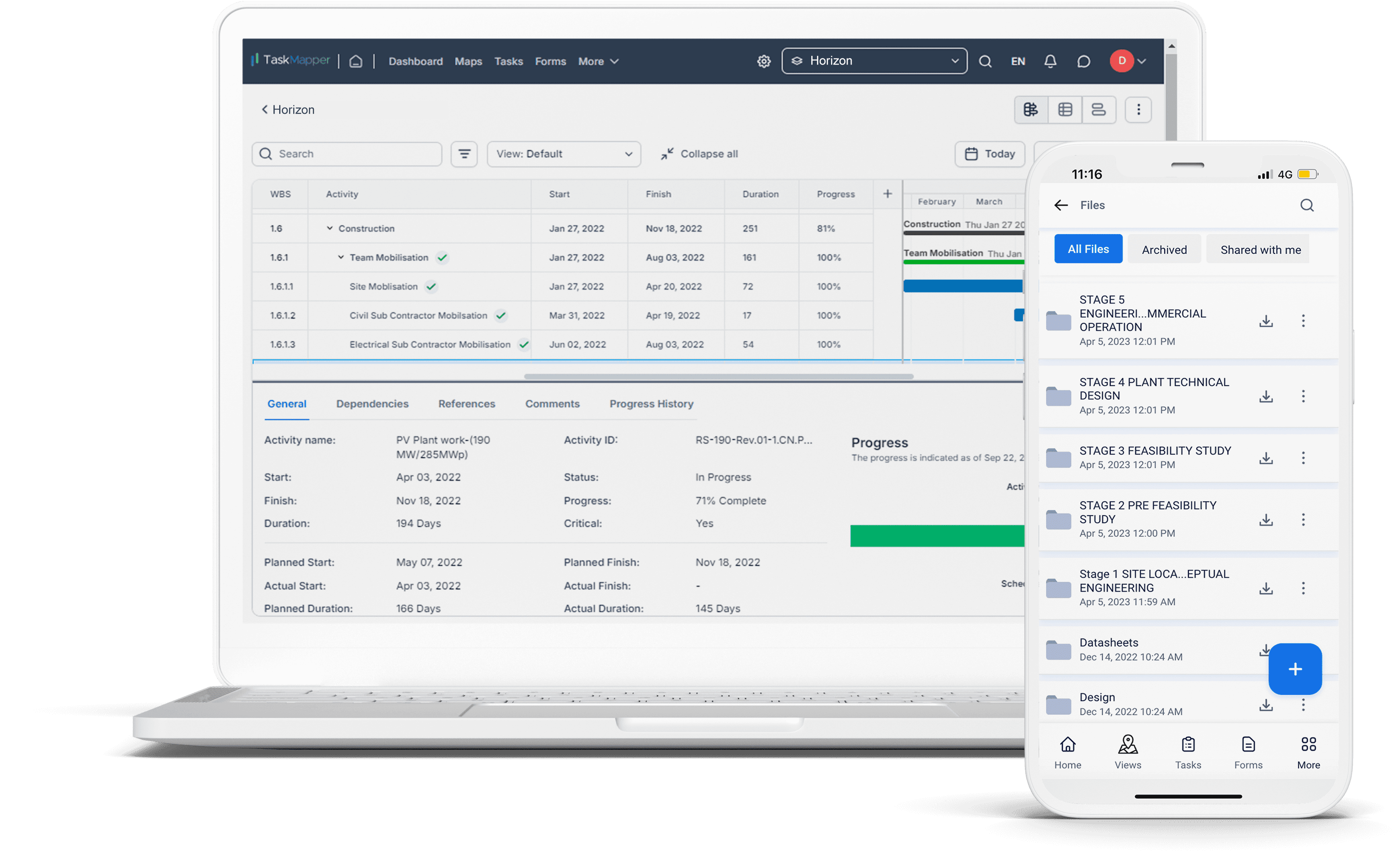

Using digital twins, documents generated during workflows can be automatically uploaded to predefined folders, simplifying access to the right data at the right time.

Lastly, the transition of critical information from phase to phase, from construction to handover, must be seamless. Ensuring comprehensive understanding and alignment among stakeholders prevents costly rediscovery of missing design and construction stage information; minimizes safety, assurance, and performance risks; and ultimately reduces operation and maintenance costs over the asset's lifespan.

Using digital twins, documents generated during workflows can be automatically uploaded to predefined folders, simplifying access to the right data at the right time.

Software Platform Functionalities Required To Create and Update Construction Digital Twins

Effectively building and maintaining construction digital twins requires a suite of software platform functionalities, including:

Proficiency in creating a virtual representation comprising models and digital assets and furnishing static data about the solar asset and its constituent components.

Deployment of a data management layer design to effectively manage static data, ensuring consistent storage, interoperability, and synchronization, fortified by a cloud-based common data environment (CDE).

Integration of dynamic data encompassing condition and performance insights derived from manual inputs, drone scans, imagery, videos, and IoT sensors (e.g., SCADA systems), which are managed by the data management layer.

Provision of data entry, analytics, and workflow functionalities for informed decision-making, facilitated through dedicated applications within the Application Module.

Incorporation of an Insights & Interface Module to analyze and visualize both structured and unstructured data sourced from the data management layer and combine use-case-specific applications to support key decisions and interventions.

Conclusion

Overall, the integration of digital twins into solar construction and handover processes can be transformative. From streamlined progress monitoring to enhanced collaboration and informed decision-making, digital twins help optimize operational efficiencies and lay the foundation for proactive asset management.

While the deployment of digital twins demands specific organizational capabilities and software platform functionalities, as highlighted by the RICS study, it provides strategic capabilities for solar stakeholders to effectively navigate complexities, mitigate risks, and ultimately, ensure the successful realization of solar projects while paving the way for a sustainable energy future.