Browse other blogs

IPP uses Therm for warranty management at solar site

South Asian power producer uses SenseHawk Therm to accelerate site inspection and warranty claims at its 10 MW solar power plant.

At a Glance

A power utility company needs to assess the health of more than 42,000 PV modules at a 10 MW solar powerplant for warranty management.

It uses the SDP-powered SenseHawk Therm to identify, classify, and geolocate defects on the digital model of the site.

Field investigations confirm that 83% of the defective modules are eligible for immediate warranty claims and that power loss in most modules is higher than the agreed degradation rate.

Problem:

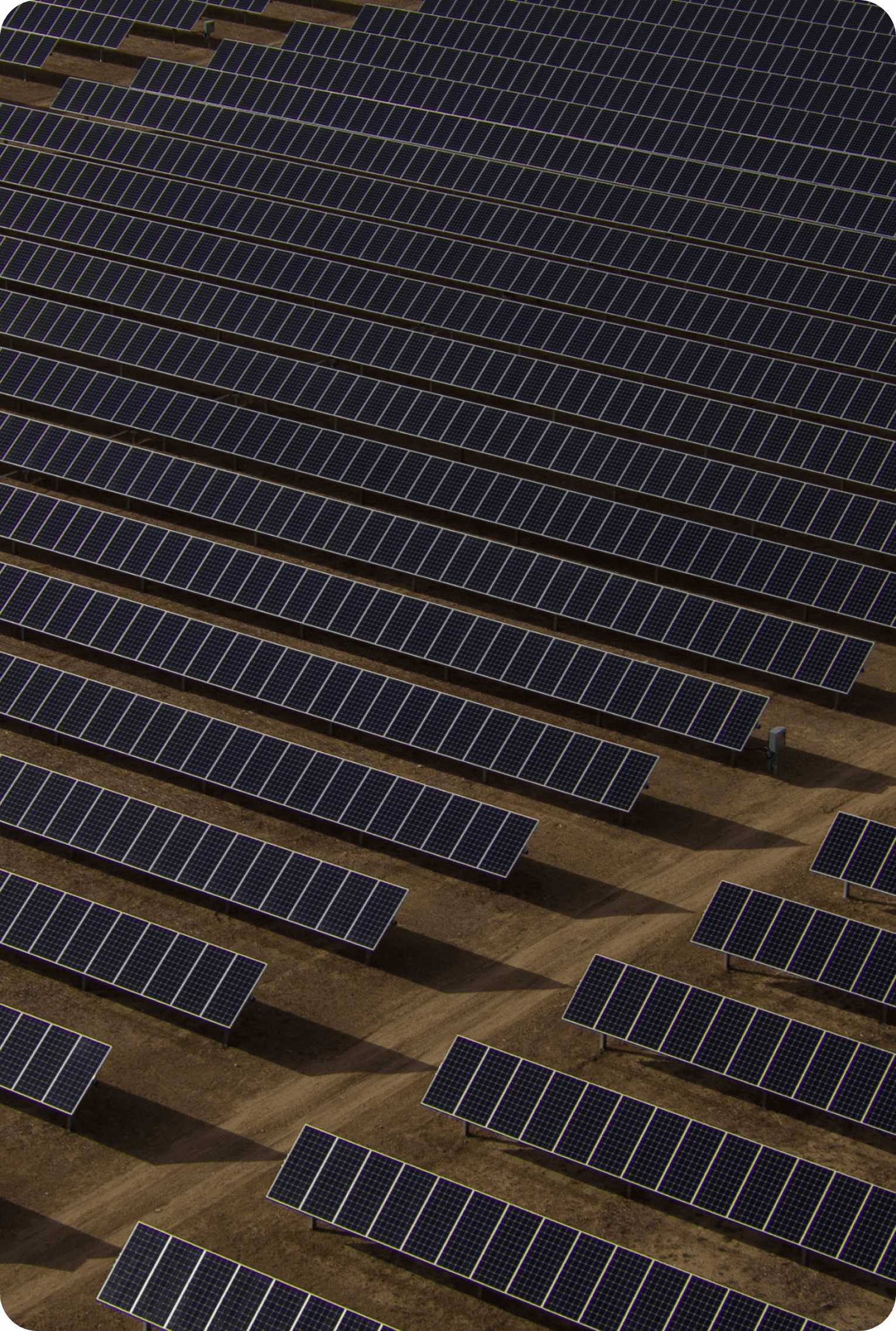

A leading independent power producer (IPP) in South Asia, with an installed capacity of 10+ GW across multiple energy sources, wants to conduct a thermographic study of one of its many projects. The 10 MW solar PV powerplant is 8 years old and spread across 45 acres.

With plans to double its installed capacity over the coming decade and increase the share of renewables in its portfolio, the utility is actively assessing and optimizing its assets. Proactive inspection and detection of mechanical and electrical defects in installed solar modules ensures in-time warranty claims and optimal productivity.

Conventional handheld thermography methods take time and a large crew to locate, investigate, report, and address defects. Even when the final reports are received, field engineers often struggle to locate the table or string number on the vast solar sites. The manual, repetitive task of collecting data for individual modules is prone to human errors. Poor network connectivity also makes onsite recording of investigation results difficult.

Map of a solar power plant enriched with layers of data from multiple sources including topography, CAD files, geo-spatial survey, and drone scans

Solution

SenseHawk Therm, powered by the SenseHawk Digitization Platform (SDP), provides drone scan-based defect detection. Infrared (IR) camera-equipped drones rapidly scan the site, and analytics help identify defects, classify them based on probable cause and issue severity, and geo-locate them on a digital model of the site on the SDP. Integrated task management, digital forms, and the fieldworker-friendly mobile app that also works in offline mode further simplify inspection and tracking.

AI/ML-based defect detection and classification to prioritize, address, and track issues efficiently

Using Therm, the utility is able to analyze the site for defects. Aerial thermographic inspections and the resulting reports enable focused field investigations. IV tracing and electroluminescence (EL) imaging tests are conducted on a sample section of 44 modules that shows 30+ high-risk and 10+ medium-risk defects. The field check confirms the defect reports and classifications on the SDP.

Accurate identification and classification of site defects; easy conversion into tasks for field crew to access on their mobile devices and address

Impact

The final Therm reports find 83% of the defective modules to be eligible for immediate warranty returns and another 10% to be eligible shortly. The field inspection also identifies accelerated degradation in the modules, with 80% of modules having power losses of 16% or more.

Armed with detailed reports and insights enabled by SenseHawk Therm, the utility follows up with the module manufacturer for claims and other relief measures to reduce the risk of module breakdowns and poor performance.

View, export or share defect reports in .csv or .pdf formats to access details including geo-location and type of defect