Browse other blogs

The Handover Binder That Builds Itself — Automating ITPs, ITCs & QC Documentation

Solar sites generate a mountain of QC and commissioning documentation:

ITPs (Inspection Test Plans)

ITCs (Inspection Test Certificates)

Torque checks

Module QC

Cable megger tests

Civil inspections

Commissioning records

Traditionally, these are captured through paper forms, scattered photos, and manual signature collection.

At COD, someone spends weeks assembling a handover binder.

TaskMapper turns this entire process into an automated workflow.

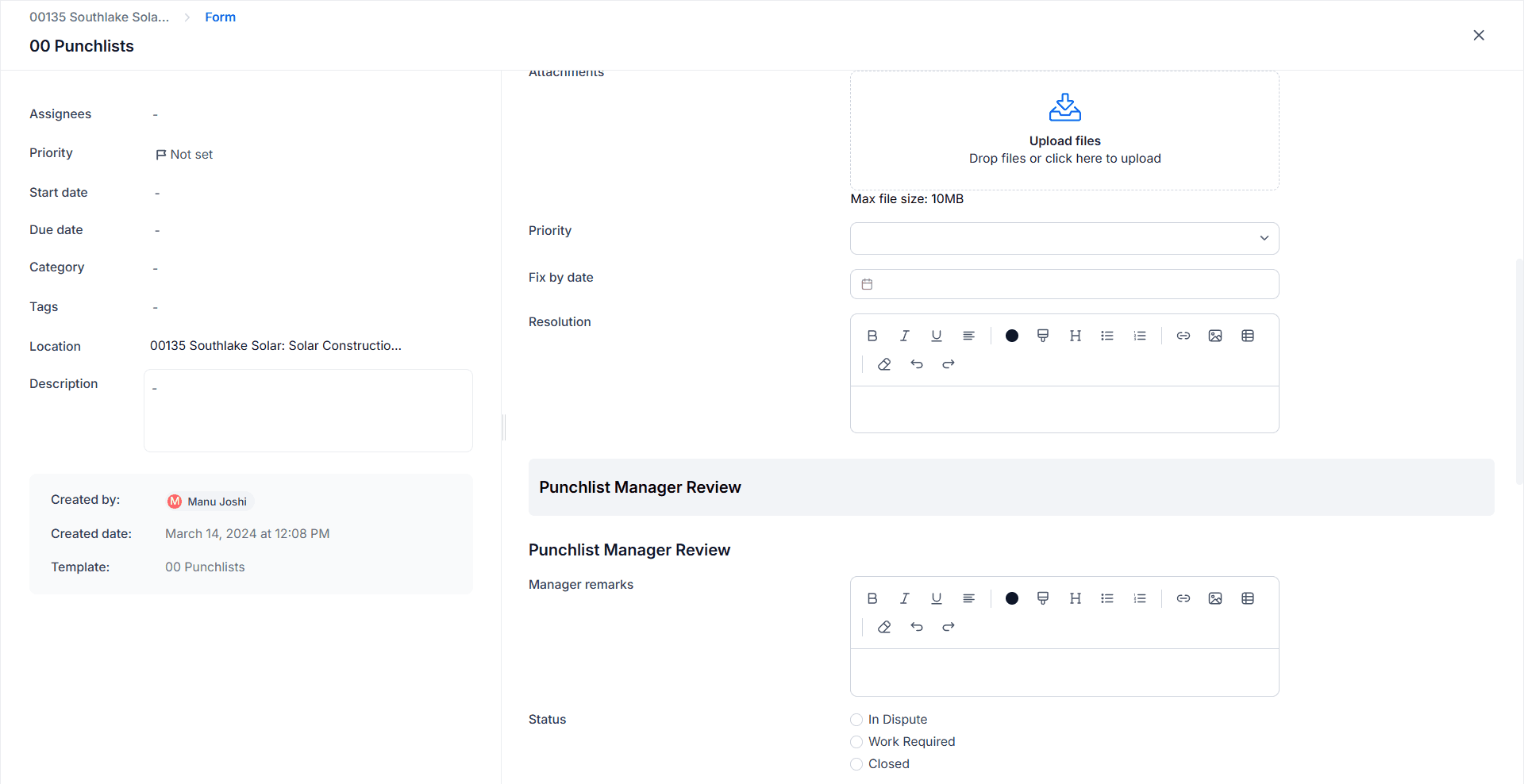

1. Field Teams Complete Digital Forms On-Site

Using TaskMapper Forms, crews capture:

Photos

GPS & time

Checklists

Observations

Digital signatures

Approval flows

Everything is structured, validated, and consistent.

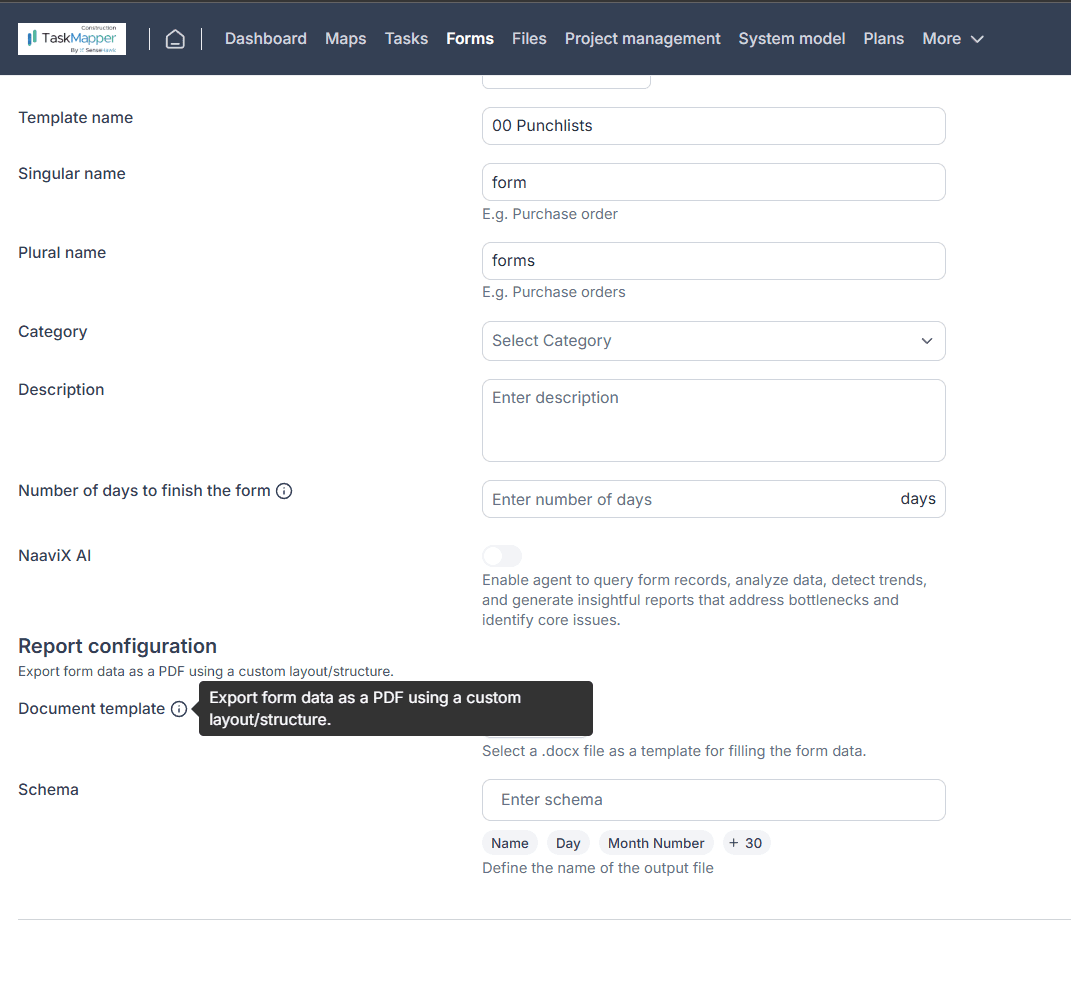

2. Auto-Generated PDFs from Your Word Templates

When a form is completed, TaskMapper automatically produces a polished PDF using your standard ITP/ITC Word templates.

These PDFs include:

Photos

Signatures

User stamps

Dates

Workflow details

No manual formatting.

No stitching documents together.

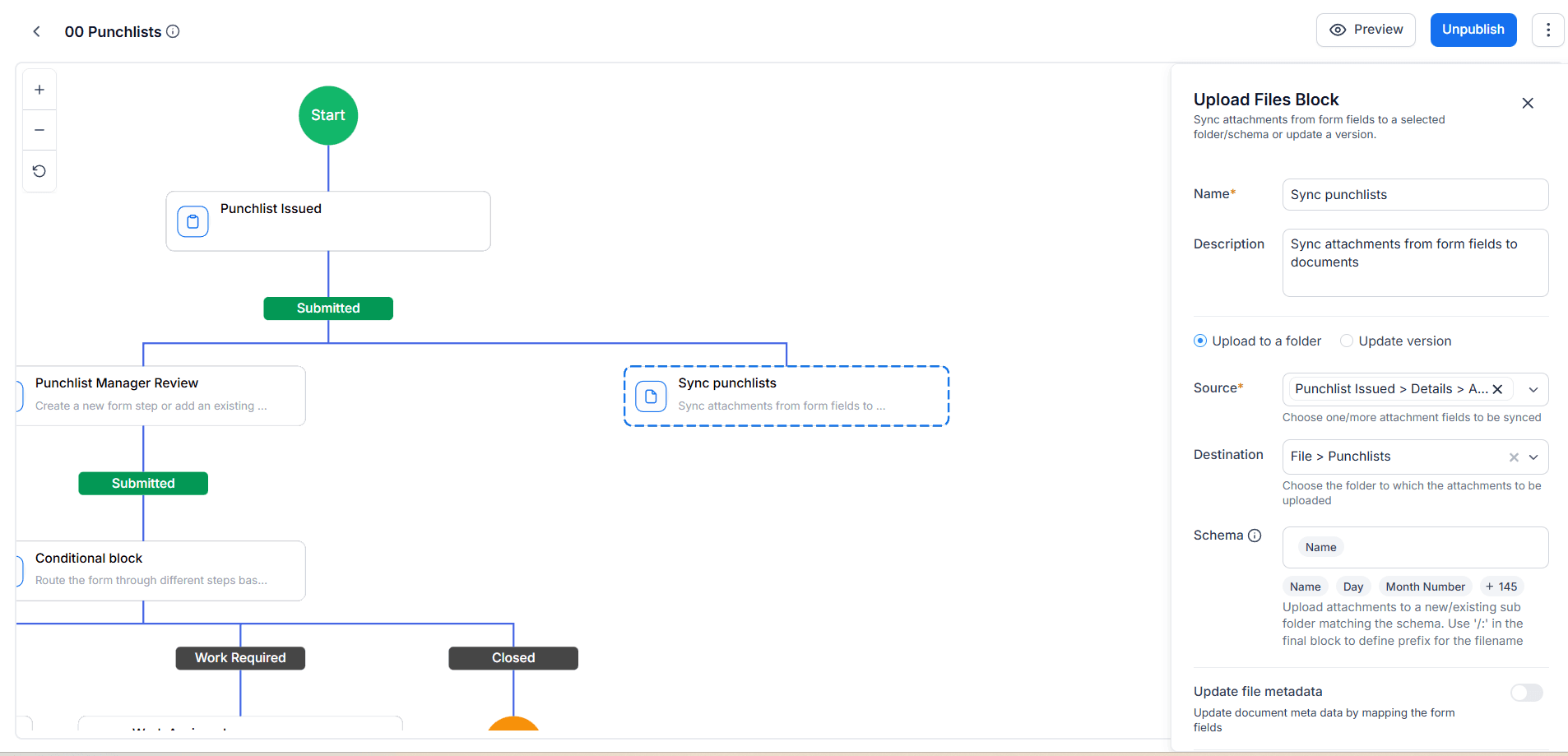

3. Delivered Into the Right DMS Folder, Every Time

Each completed report is routed automatically into the correct DMS location, such as:

QC → Mechanical → Torque Checks

QC → Electrical → ITCs

Commissioning → Block 4 → IV Curves

Zero manual filing.

Zero lost documents.

4. Each Record Is Linked to the Digital Twin

Because every form ties to an asset in the System Model, the final QC history becomes part of the digital twin:

Piles

Modules

Tracker rows

Inverters

Transformers

MV runs

At handover, the digital twin contains the complete as-built and QC record — without extra work.

By COD, the Handover Binder Already Exists

No scrambling.

No missing documents.

No manual assembly.

Asset Management inherits a living digital twin with full traceability — from the first pile installed to the final commissioning test.

To find out more about how you can create an “assembly line” process for your QC documentation - book a demo to find out more.