Browse other blogs

Why Every Solar Project Needs a Digital Twin

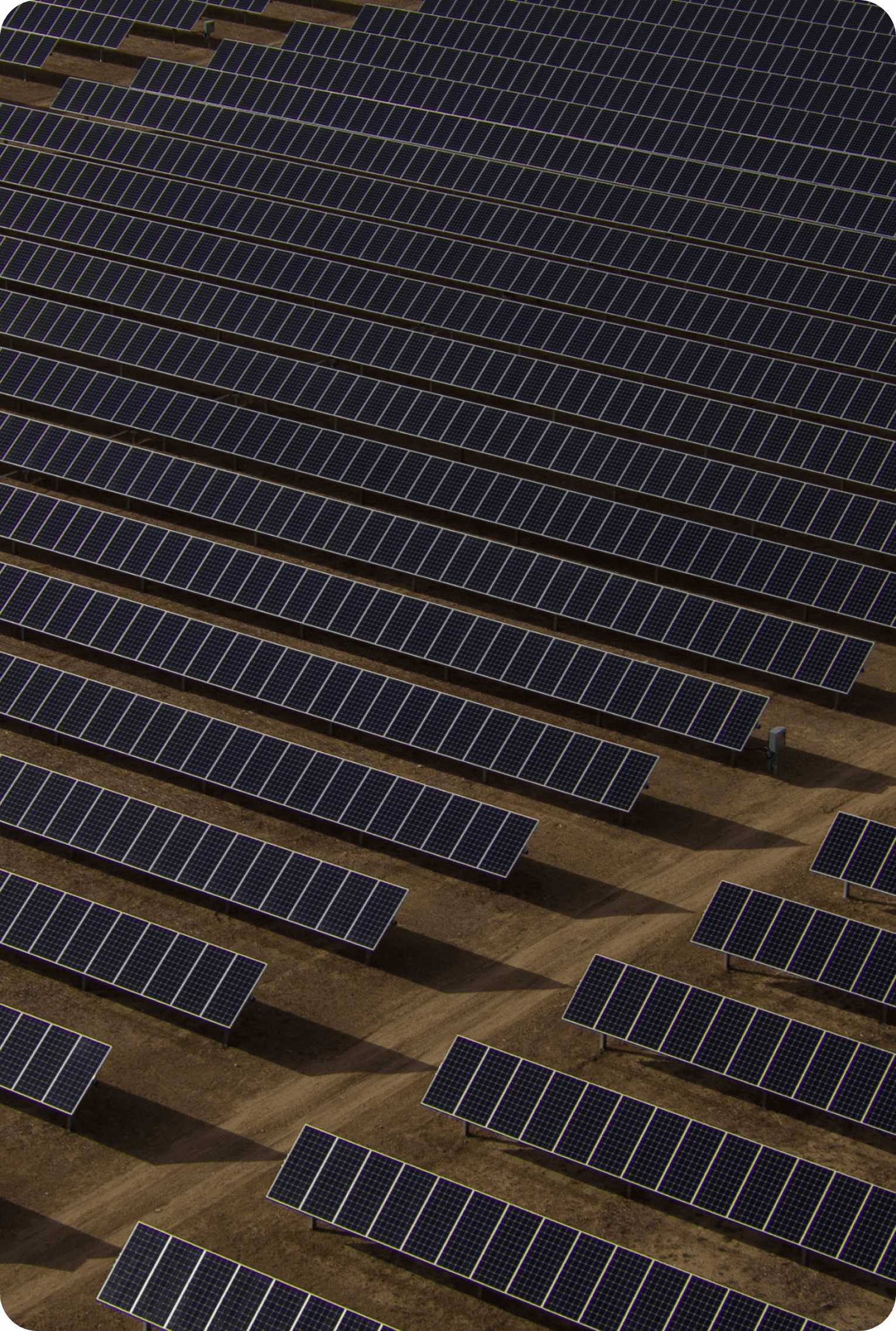

Solar projects today are bigger and more complex than ever before. With thousands of modules, miles of cabling, dozens of contractors, and tight deadlines, it’s no surprise that projects often suffer from delays, rework, and fragmented data.

Traditionally, each team manages its own silo:

Engineering maintains CAD drawings and layouts

Construction Management maintains Daily Production Reports (usually in excel)

Planning & Scheduling maintains the Project Schedule using a PM tool (MS Projects/ Primavera)

Quality control logs issues in spreadsheets and punch lists

Asset Management and O&M receives a handover package that’s often incomplete or outdated

The result? A constant struggle to connect the dots across design, construction, commissioning, and operations.

Enter the Digital Twin for Solar

A Digital Twin is more than a buzzword. It’s a living, digital representation of the solar plant that integrates design files, construction progress, inspection data, and operational insights into one system-of-record. Here’s what that means in practice:

Unified View: From modules and strings all the way to inverters and substations, every component is represented digitally and linked to its documents, warranties, and inspection history.

Construction Monitoring: Drone orthomosaics and survey data overlay directly onto the digital twin, highlighting deviations in real time. No more waiting weeks to find out what’s gone wrong in the field.

QC Made Easy: Digital inspections, with photos, geotags, and checklists, are tied directly to assets in the twin. Every NCR, approval, and corrective action is logged and auditable.

Seamless Handover: Instead of stacks of PDFs, O&M inherits a complete digital record — including IV curves, thermal scans, and commissioning reports — all linked to the equipment they’ll manage.

Predictive Operations: Once in O&M, the twin becomes the foundation for thermal analytics, vegetation monitoring, and predictive maintenance.

Why It Matters

A Digital Twin is not just about having better data — it’s about making better decisions faster.

Developers reduce delays and accelerate COD.

EPCs cut rework by catching issues early.

O&M teams improve plant uptime with targeted, data-driven interventions.

Asset managers finally get portfolio-wide visibility that’s consistent and reliable.

At SenseHawk, our TaskMapper platform is built around this vision — a Digital Twin for Solar that covers the entire lifecycle: pre-construction, construction, commissioning, operations, and even end-of-life planning.

The solar industry can’t afford to work in silos anymore. With gigawatts of new projects being built every year, Digital Twins are becoming the digital backbone of utility-scale solar.

Want to see how a Digital Twin can change the way you build and operate solar assets? 👉 book a demo here.