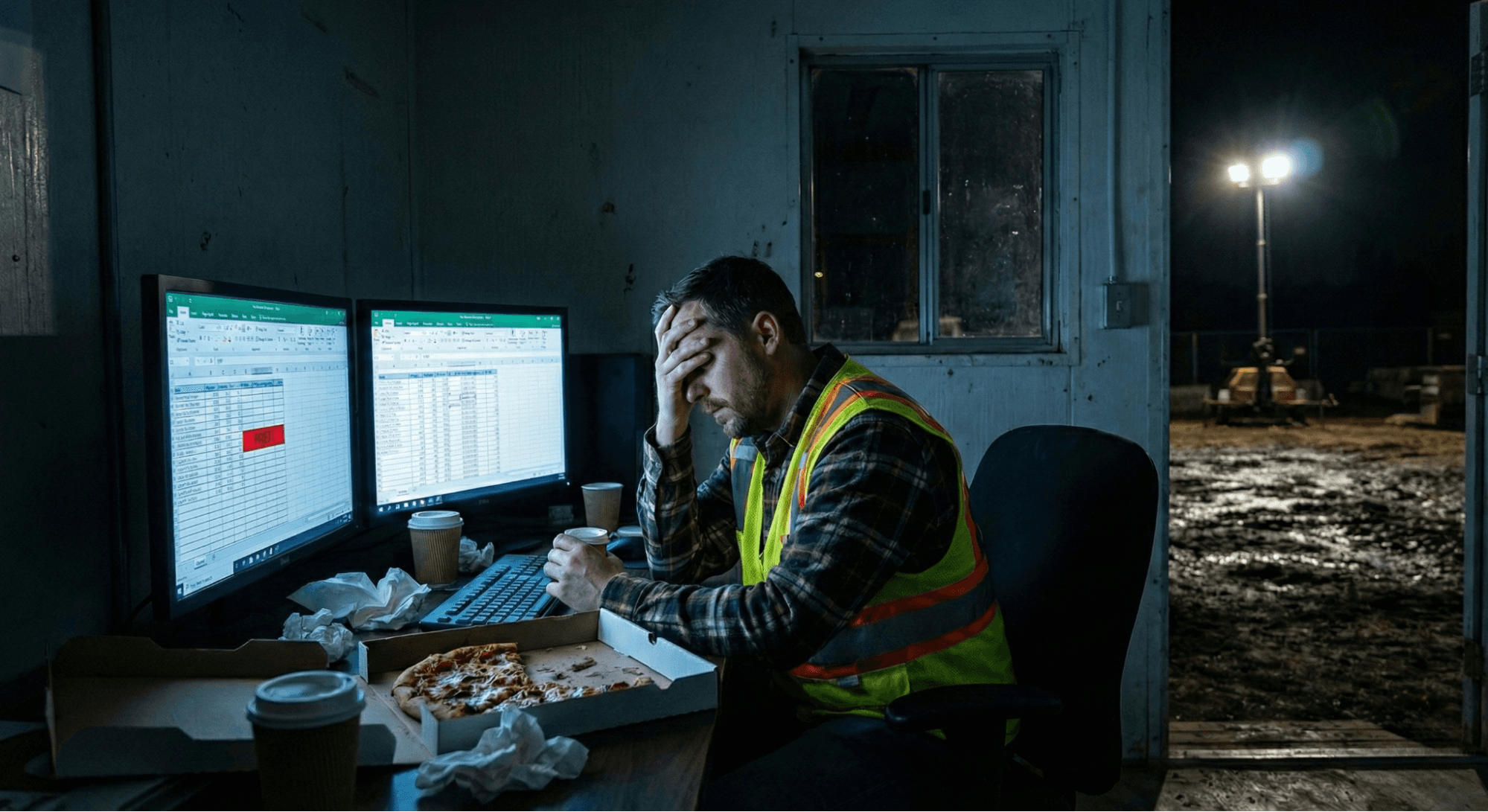

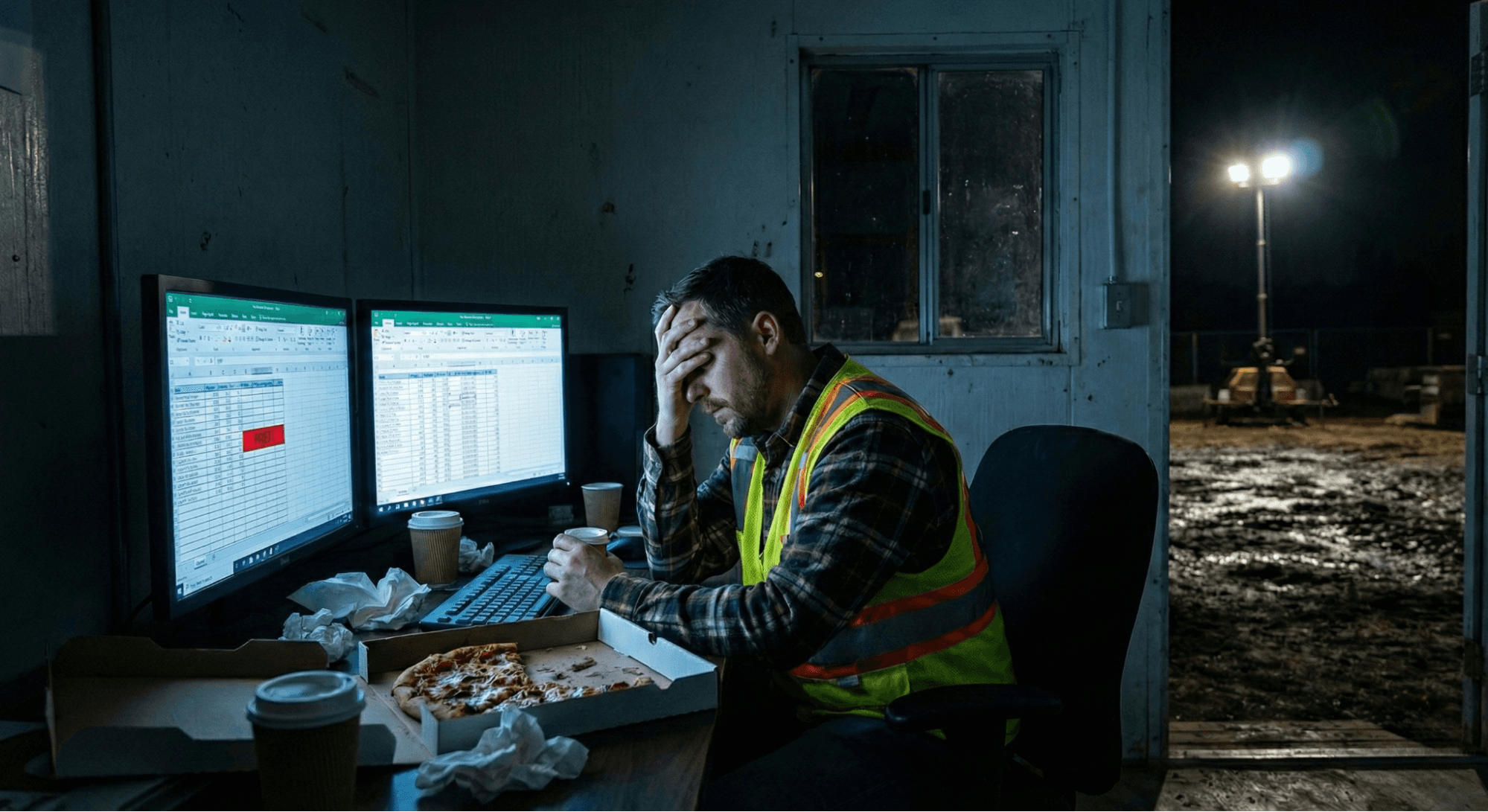

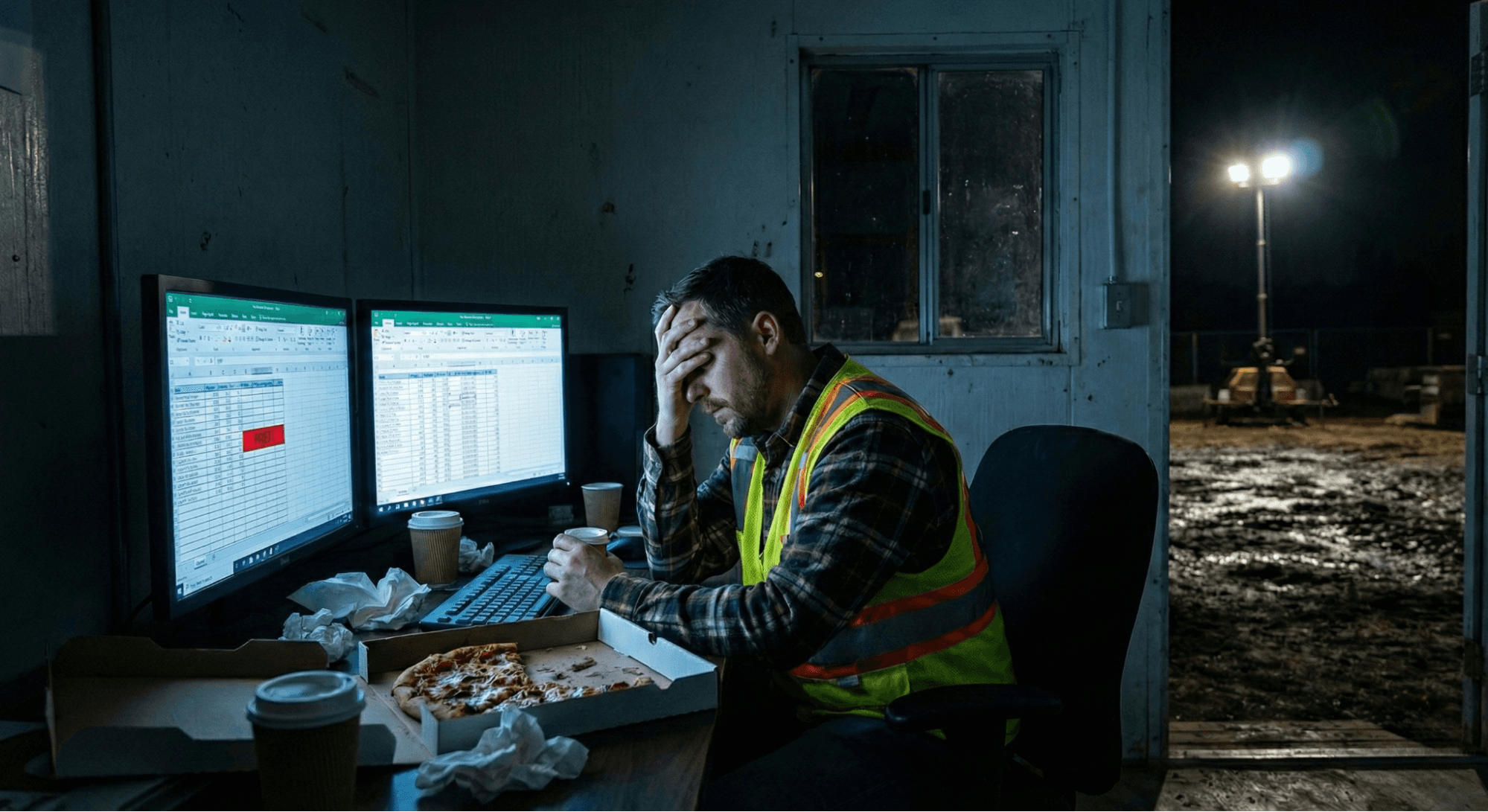

The Friday Night Spreadsheet Rodeo: Why Your Highest-Paid People Are Doing the Lowest-Value Work

The "Friday Night Spreadsheet Rodeo" sees high-value Project Managers wasting 10–15 hours weekly as "Data Janitors," manually stitching siloed data from P6, ERPs, and field notes. This leads to the "Monday Morning Lie"—a report that is obsolete the moment it's presented. TaskMapper replaces this manual "spreadsheet wrangling" with an automated data engine that aggregates progress in real-time. By providing a single source of truth, TaskMapper frees your team from low-value robot work so they can focus on strategic engineering and project execution.

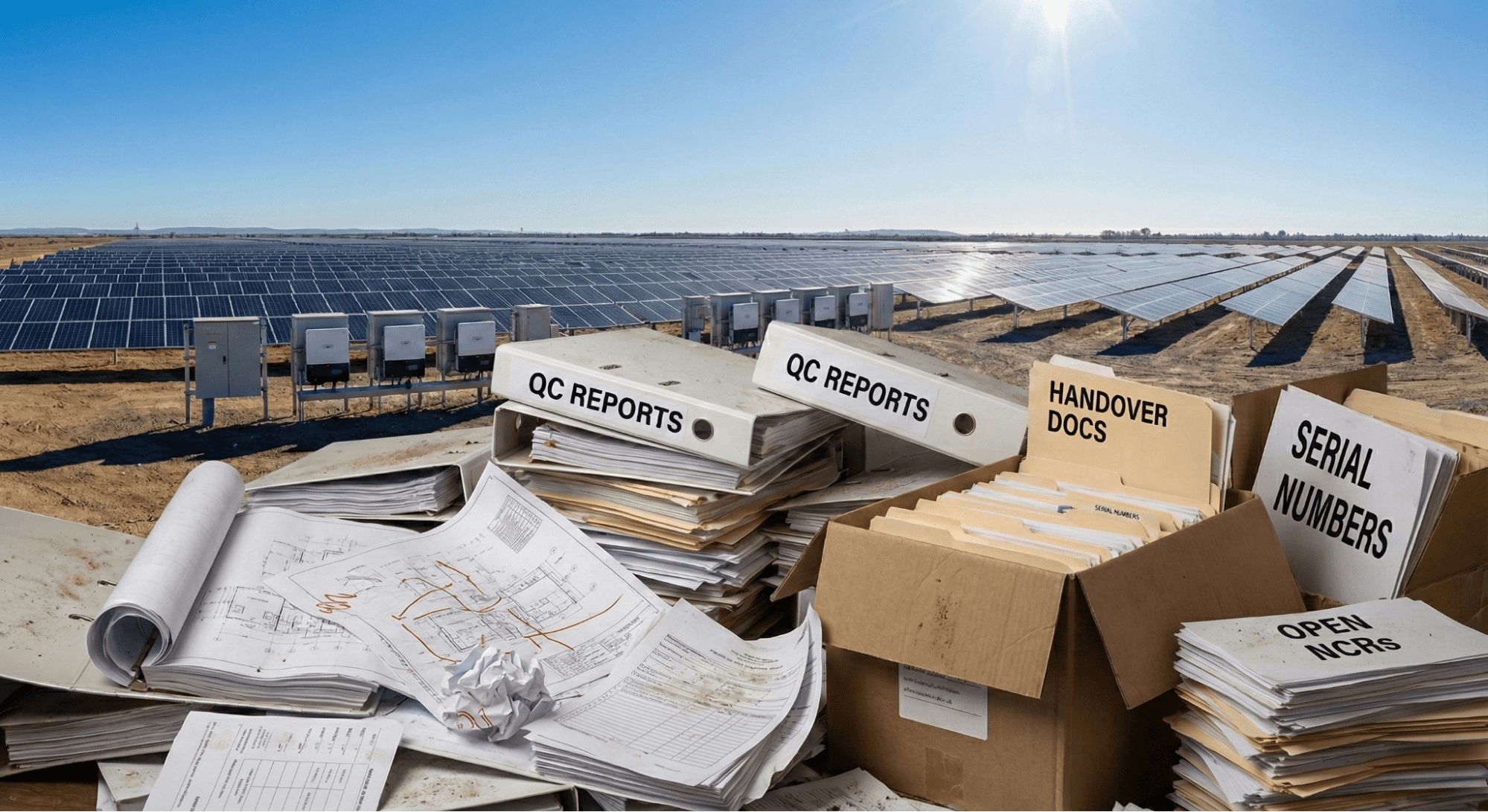

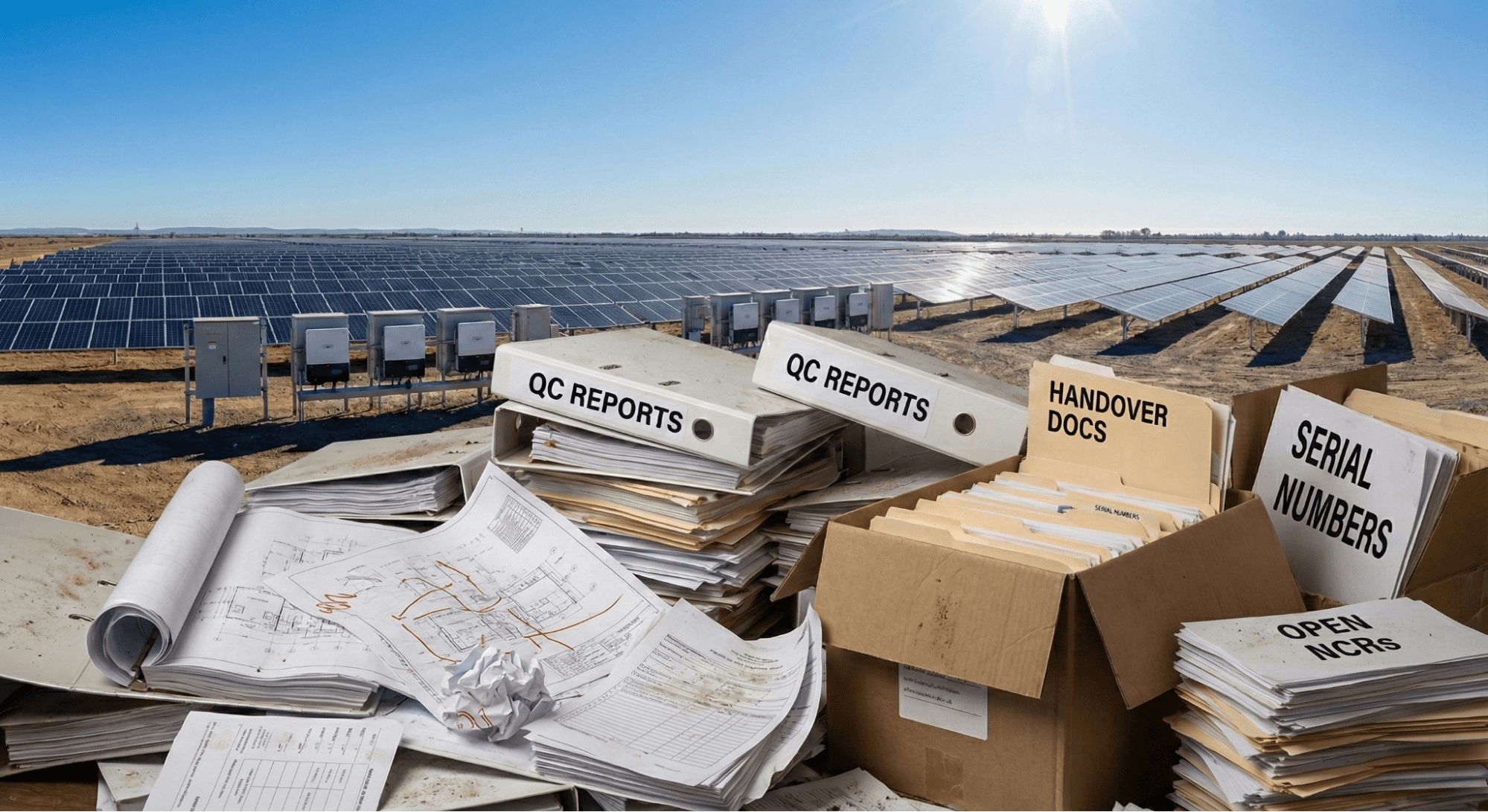

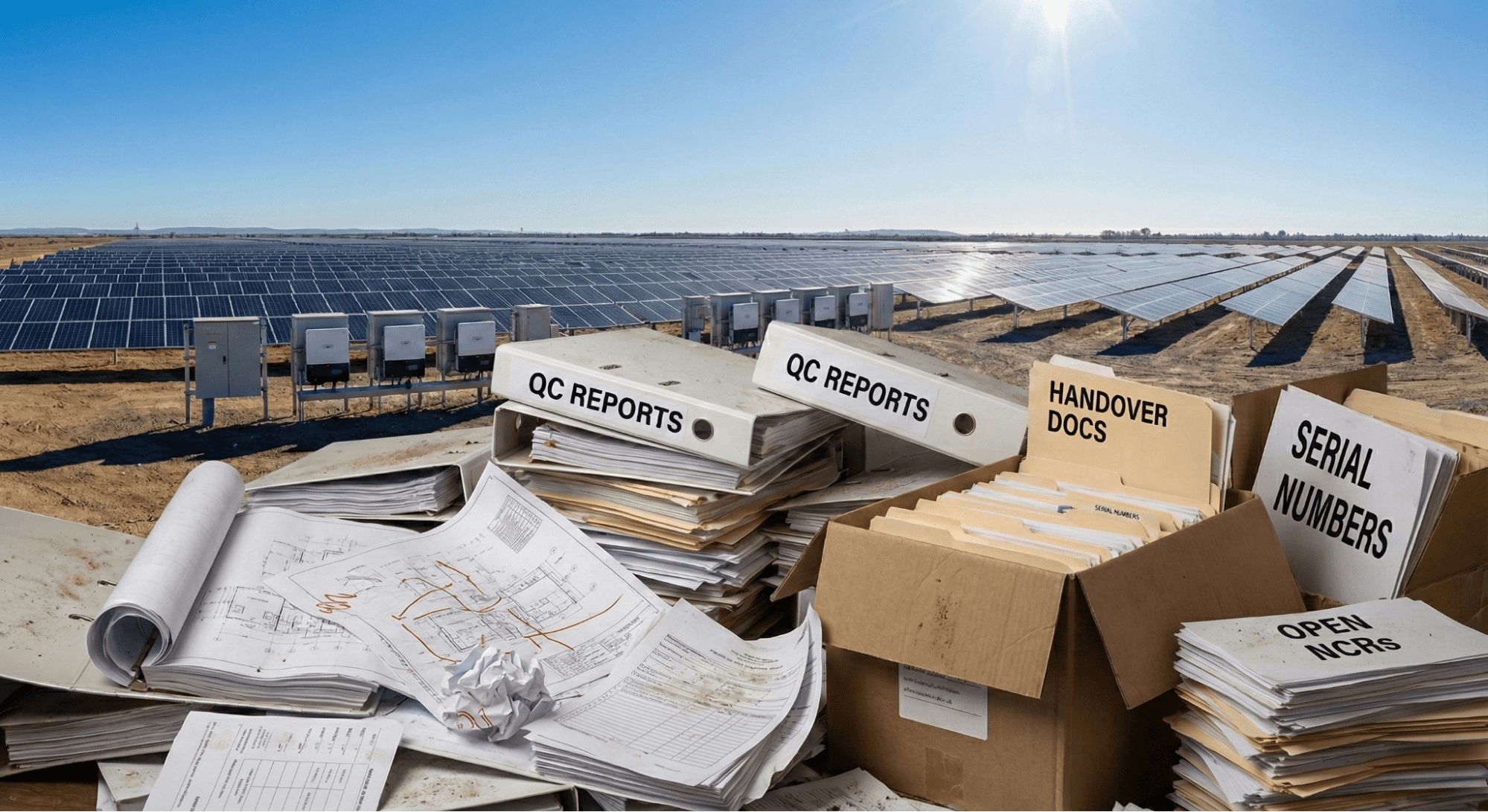

The Zombie Project: Why You’re Stuck at 99% Complete (And How to Escape)

The "Zombie Project" is physically finished but stuck at 99% because the Digital Asset (QC forms, redlines, serial numbers) is a disaster. This "Closeout Hell" locks up your profit in unpaid retainage while you scramble to reconcile data. TaskMapper kills the Zombie Project by building the digital and physical assets simultaneously. By linking every inspection and NCR to the Digital Twin in real-time, the handover package builds itself daily—ensuring you hit Final Acceptance, demobilize on time, and secure your cash flow.

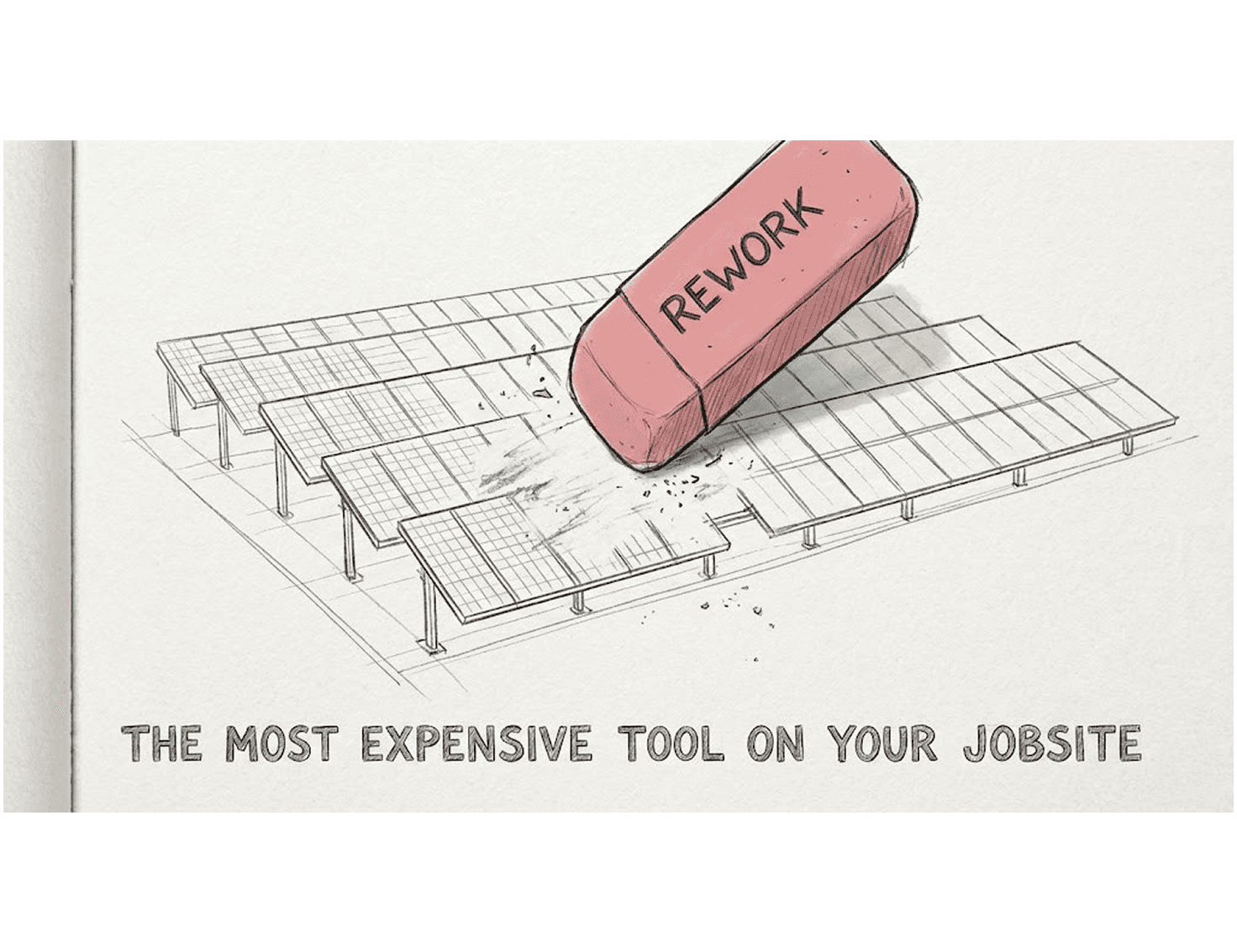

The Most Expensive Three Words in Solar: "Do It Over."

Rework—costing up to three times the original build—is caused by the gap between Engineering (Design) and the Field. When crews use outdated drawings, they hit production targets but build errors that require demolition. TaskMapper closes this gap by syncing CAD/GIS data directly to field apps, ensuring everyone uses the latest revision. By overlaying As-Designed vs. As-Built data in real-time, the system catches deviations like pile height or alignment errors before they scale, turning your dashboard into a proactive quality defense rather than just a progress tracker.

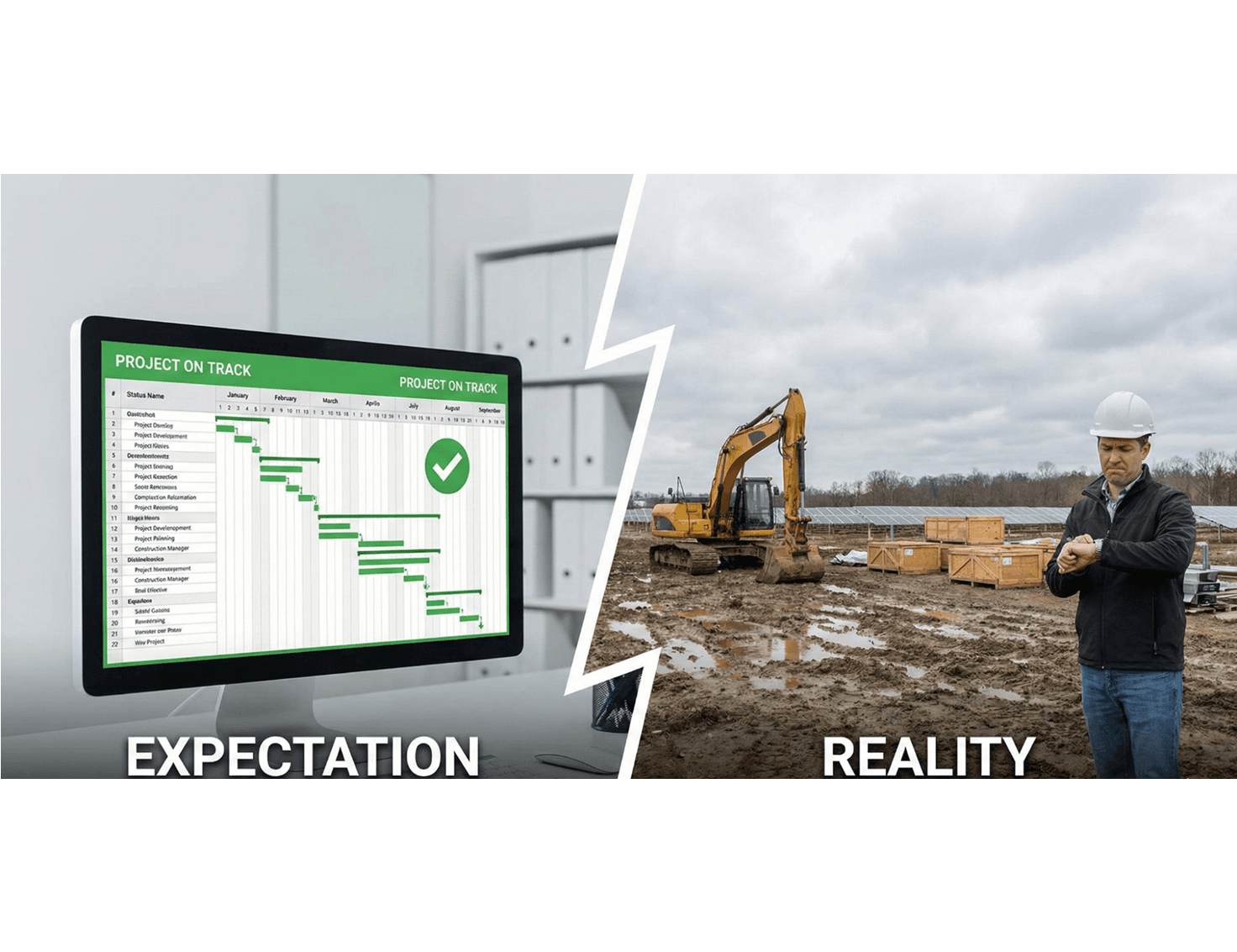

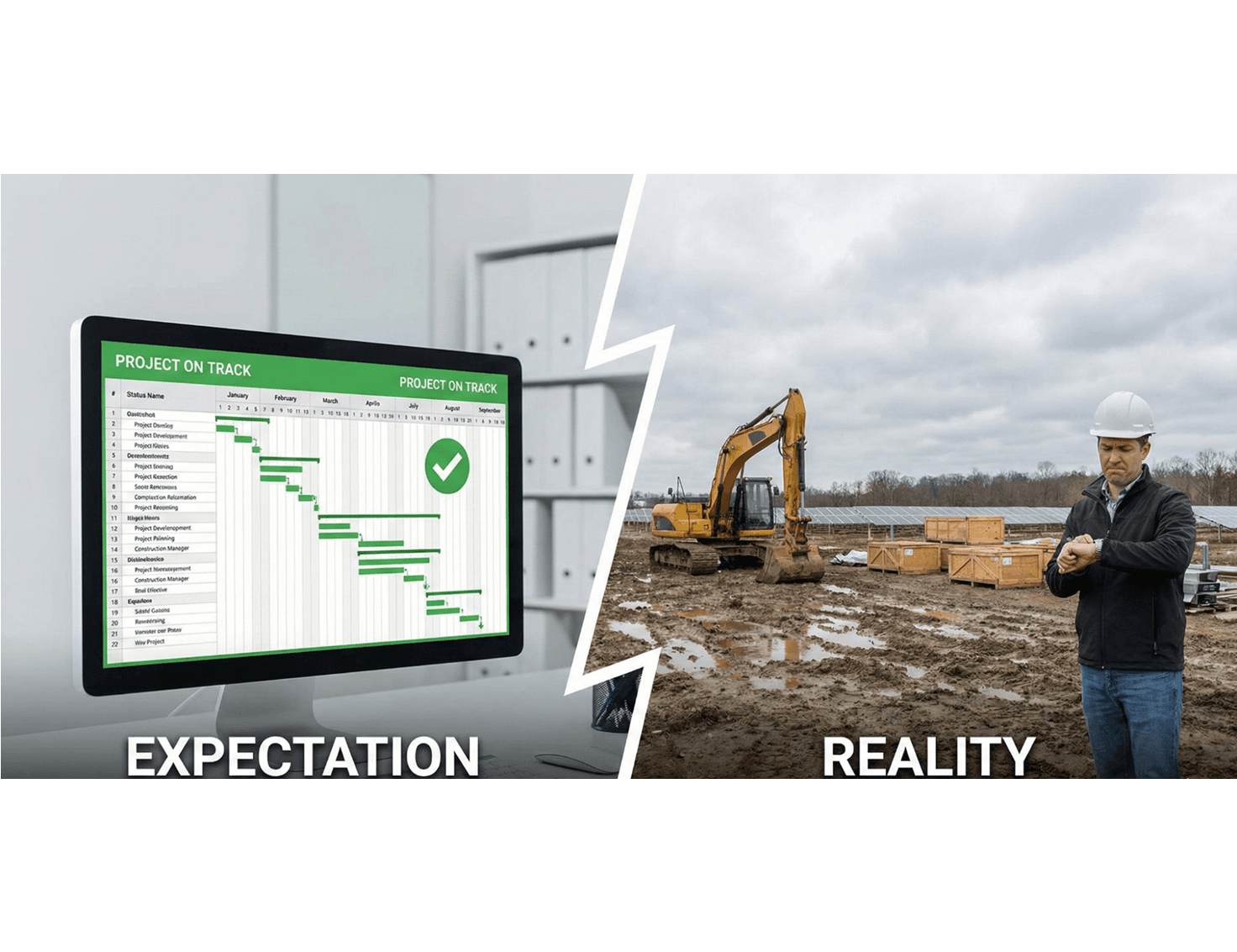

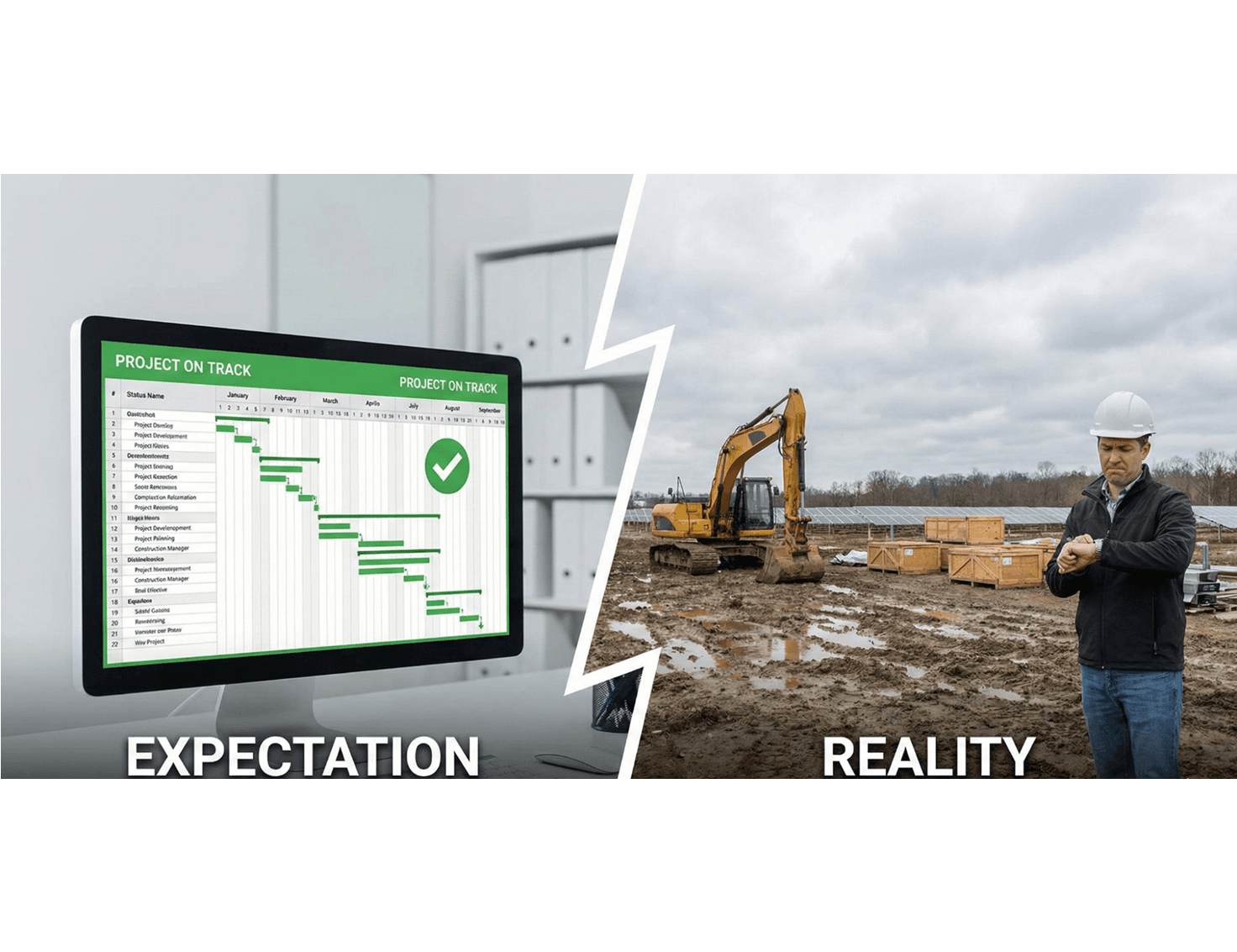

The Phantom Delay: Why Your Schedule Says "Go" but Your Site Says "Stop"

TaskMapper eliminates the "Coordination Tax" by breaking the silos between Schedule (P6), Engineering (CAD), Procurement (ERP), and Field Operations. It prevents "Phantom Delays"—where schedules show "go" but crews sit idle—by syncing procurement realities with the construction timeline. By integrating these four streams, TaskMapper ensures that lead-time changes or shipping delays are immediately visible, allowing teams to proactively re-sequence work and avoid costly labor downtime.

The Death of the Static Dashboard: Why Solar Construction Needs a Decision Engine, Not Just a Report

TaskMapper BI replaces static reports with a real-time decision engine built for solar construction. By integrating design, procurement, field progress, and schedules into the Digital Twin, it breaks down data silos to reveal the "why" behind delays. Teams can drill down from high-level trends to root causes—like specific contractor issues or material shortages—in seconds. This creates a single source of truth that moves project teams from reactive reporting to proactive risk mitigation and execution.

The 12 Days of Solar Construction (TaskMapper Edition)

TaskMapper wrapped up the year with a festive "12 Days of Solar Construction" song, playfully highlighting its core features, including the digital twin, synced schedules, ITPs, automated forms, pile alignment, and successful inventory management. This lighthearted message celebrates the industry's progress in digitalizing solar construction. Happy Holidays!

TaskMapper: Streamline Mechanical Activities During Solar Construction

Overview of mechanical activities in solar energy project construction, including installing mounting structures to house PV panels, and how TaskMapper simplifies monitoring, updates, and reporting for EPC contractors.

Streamlining Civil Activities in Solar Project Construction With TaskMapper

Key civil activities in solar energy project construction, including road development and fencing and how TaskMapper simplifies their monitoring and reporting to enhance efficiency and tracking for EPC contractors.

TaskMapper Transforms Pre-Construction for Solar EPC Contractors

The pre-construction phase of solar projects can be complex and time-consuming. TaskMapper simplifies site surveys, land preparation, planning, progress tracking, and team collaboration to boost efficiency.

Work Anywhere: How TaskMapper Mobile Powers Offline Field Operations

TaskMapper Mobile is an offline-first app that ensures field operations continue seamlessly in areas with no network coverage. Teams pre-load work (maps, ITPs/ITCs, tasks) and can fully complete QC inspections, capture geotagged photos, and create new tasks while offline. All data is stored locally and automatically syncs when connectivity is restored, providing instant progress updates and full data traceability within the Digital Twin.

The Handover Binder That Builds Itself — Automating ITPs, ITCs & QC Documentation

TaskMapper automates the Handover Binder by digitizing QC and commissioning records (ITPs, ITCs). Field teams use digital forms on-site, which the system uses to auto-generate PDFs using your templates and automatically file them in the correct DMS folders. Crucially, every record is linked to the Digital Twin, providing Asset Management with a complete, traceable, and ready-made as-built and QC record by COD.

Fixing Document Chaos — Bringing Version Control to Solar Construction

TaskMapper's Document Management System (DMS) establishes a Single Source of Truth for solar construction by enforcing structured version control for all design documents (IFCs, RFIs, permits). It ensures field crews only see the latest revision, digitally tracks all approvals, and links documents directly to the Digital Twin. This eliminates the use of outdated drawings, drastically reduces rework, and turns document control into a powerful quality control function.

Managing the Interconnection Process for Utility-Scale Solar Projects

The interconnection process is essential in utility-scale solar development to ensure seamless integration into the electrical grid and this blog explores its intricacies and how TaskMapper simplifies it.

TaskMapper to Manage Securing Process for Right of Way for Transmission Line

TaskMapper simplifies process management for securing the right of way for transmission lines in solar projects. From assessment to acquisition, it improves land acquisition efficiency and clarity.

TaskMapper To Simplify Land Acquisition Processes for Large Solar Projects

Land acquisition involves assessing land use, transmission access, and water rights for solar project development. This blog explores how TaskMapper helps streamline process management.

Design Meets Reality: How Automatic Redlines Catch Construction Deviations Early

TaskMapper's Automatic Redlines uses weekly drone scans and the digital twin to instantly detect construction deviations from the IFC/CAD design (e.g., pile positions, tracker alignment). It generates geospatially precise redlines that automatically convert into assignable QC items or corrective tasks. This process minimizes rework, prevents design violations, and ensures a continuously updated as-built record.

Building Solar With Certainty: End-to-End Material Traceability on Construction Sites

TaskMapper Inventory Management is a construction-ready tool for utility-scale solar, providing end-to-end material traceability from shipment to installation. It tracks materials across laydown yards, links all component movements and serial numbers to the project's Digital Twin, ensuring a continuous, accurate Bill of Materials. This specialized system eliminates shortages, replaces manual tracking, and provides auditable documentation for quality and warranty purposes.

Building the Digital Twin Before the First Pile: A Smarter Way to Commission and Handover

The Digital Twin for Solar is built by SenseHawk from the start of construction, integrating the plant's electrical and mechanical System Model with the site Map to track all construction history and QC. Commissioning is performed directly on the Twin using digital workflows tied to specific assets, resulting in the Twin automatically serving as the seamless handover package to O&M, eliminating data gaps and providing a complete, verified record for proactive asset management.

Streamline and Manage Complex Solar Project Development Workflows with TaskMapper

The project origination and development workflow is the backbone of the solar asset lifecycle. This blog explores the intricacies of the process and how TaskMapper can be a game-changer in streamlining it.

Digital Twins: Game-Changers in Solar Construction and Handover

In the solar PV sector, digital twins are predominantly associated with operational assets and maintenance. However, they can play an equally valuable role during the construction phase of solar assets.

10 Ways TaskMapper Helps Solar Project Managers During Construction

To maximize the ROI on solar PV projects, project managers need to ensure that every aspect of asset construction is completed on time, within budget, and without compromising on build quality.

From Manual Updates to Autonomous Progress: Using Drones for Construction Tracking

Solar projects are automating progress tracking using scheduled drone flights (including autonomous "drones-in-a-box") to capture imagery. Taskmapper processes this data to enable automated activity detection (e.g., pile installation) and instantly updates the P6 schedule and dashboards. This shifts field engineers from manual reporting to high-value validation and oversight, creating a continuous, data-driven construction site.

Ending the Weekly Markup: Linking Construction Updates Directly to the P6 Schedule

Taskmapper automates solar project scheduling by allowing users to import P6/MS Project files and link activities directly to spatial locations on the map and detailed field workflows. As crews log geotagged progress updates via the mobile app, the system automatically updates the master schedule in real-time, eliminating manual reconciliation and providing planners with instant, accurate, and auditable status reports.

Turning Up the Heat on Rare Thermal Signatures

Solar thermal inspections are increasingly revealing rare and unusual thermal signatures—such as unique heating patterns in bifacial and half-cut modules, or dark material-concern patches—that deviate from standard issues. These anomalies have critical, undocumented implications for system performance and reliability, requiring solar professionals to understand and address them to protect yield and warranties.

Streamline complex construction and operations with end-to-end digitization

Project managers, contractors, and EPCs at construction companies struggle to track all project aspects, including logistics, scheduling, monitoring, and communication. Digitization is the solution.

5 Ways SenseHawk Drone Analytics Empowers Solar Asset Stakeholders

SenseHawk Drone Analytics helps extract actionable insights from solar sites to enable stakeholders to drive down costs and optimize operations.

Key Strategies for Effective Solar Project Construction Management

Discover key strategies for successful solar project construction management. Assess your current processes to identify areas to improve.

Automating QC: How One EPC Digitized Their Entire Construction Workflow

An EPC client digitized their solar QC using Taskmapper, integrating imported CAD layers with linked construction workflows directly on a site map. This process automated progress tracking and embedded digital QC forms requiring geotagged photos and signatures at every step. The system automatically compiles complete, branded, and auditable QC reports, simultaneously linking progress updates to the main Project Schedule.

Why Every Solar Project Needs a Digital Twin

The Digital Twin for Solar unifies fragmented project data, acting as a single, living digital representation of a solar plant across its lifecycle. It integrates design, real-time construction monitoring (via drone data), and geotagged QC inspections into one system-of-record. This unified approach eliminates data silos, cuts rework, provides a seamless digital handover to O&M, and ultimately accelerates COD and improves plant uptime.

Building Confidence in Pile Quality

Taskmapper digitizes and streamlines solar project pile installation and QC, replacing spreadsheets with a real-time project map visualization. Automated workflows track progress, guide quality checks with required photo and signature capture, and ensure accuracy and accountability. The system automatically generates and saves the final QC report to the DMS, providing a single source of truth and eliminating manual errors.

Simplified Solar Asset Work Management and Reporting with TaskMapper

TaskMapper offers an integrated solution for managing work and reporting throughout the solar asset lifecycle.

TaskMapper identifies and meets the diverse needs of solar PV stakeholders

The solar PV project lifecycle involves multiple stakeholders, and accurately meeting their needs significantly increases the value derived from the asset.

TaskMapper : GIS-powered site planning and as-built monitoring

Map-based terrain analysis and construction monitoring improves planning, collaboration, and tracking for successful execution of solar projects.

SenseHawk's New Document Management Solution: Enhancing Efficiency in Solar Projects

The new DMS system integrates eamlessly with the TaskMapper platform and is a comprehensive solution to enhance the efficiency and security of document management in solar projects. It centralizes documentation and simplifies access throughout the asset lifecycle.

Best Practices for Smooth Functioning of Solar Assets After Weather Events Like Hail and Hurricanes

Best practices in site planning, design, and operations protects solar investments from weather-related damage. In case of EWE, TaskMapper equips teams with tools for swift recovery.

Manage Solar Project Due Diligence with TaskMapper

TaskMapper helps simplify due diligence for solar projects. From legal reviews to technical assessments, it streamlines workflows, digitizes approvals, and keeps teams aligned for compliance and efficiency.

Digital tools for solar construction in the post COVID era

How the SenseHawk Digitization Platform helped clients minimize project-lifecycle related obstacles and associated risks in the first 12 months of the pandemic.

Findings from 14 GW of thermography in 17 countries

Insights from drone inspections and analytics capabilities of the SenseHawk Digitization Platform at various sites across countries and technologies.

SenseHawk remediates defects at 8th largest solar powerplant

SenseHawk helps with defect identification, classification, and prioritization for faster remediation at the 8th largest solar power plant in the world at the time.

Vertical SaaS in Solar Asset Management: Revolutionizing Efficiency and Integration

Vertical SaaS solutions like TaskMapper address key challenges for solar operators, integrating functions seamlessly across project phases and providing real-time insights for smarter decision-making.

Simplify Solar Project Financial Processes with TaskMapper

Utility-scale solar project fianacing spans stages from development and due diligence to construction monitoring and loan repayment. TaskMapper streamlines collaboration and ensures compliance with lender conditions for timely loan disbursement.

Drone Analytics in Solar Construction and O&M

Drone data is transforming utility-scale solar asset management. From construction monitoring to O&M workflows, TaskMapper’s drone analytics optimizes project management using high-res maps, actionable insights, and task management.

The Phantom Delay: Why Your Schedule Says "Go" but Your Site Says "Stop"

TaskMapper eliminates the "Coordination Tax" by breaking the silos between Schedule (P6), Engineering (CAD), Procurement (ERP), and Field Operations. It prevents "Phantom Delays"—where schedules show "go" but crews sit idle—by syncing procurement realities with the construction timeline. By integrating these four streams, TaskMapper ensures that lead-time changes or shipping delays are immediately visible, allowing teams to proactively re-sequence work and avoid costly labor downtime.

The Death of the Static Dashboard: Why Solar Construction Needs a Decision Engine, Not Just a Report

TaskMapper BI replaces static reports with a real-time decision engine built for solar construction. By integrating design, procurement, field progress, and schedules into the Digital Twin, it breaks down data silos to reveal the "why" behind delays. Teams can drill down from high-level trends to root causes—like specific contractor issues or material shortages—in seconds. This creates a single source of truth that moves project teams from reactive reporting to proactive risk mitigation and execution.

The 12 Days of Solar Construction (TaskMapper Edition)

TaskMapper wrapped up the year with a festive "12 Days of Solar Construction" song, playfully highlighting its core features, including the digital twin, synced schedules, ITPs, automated forms, pile alignment, and successful inventory management. This lighthearted message celebrates the industry's progress in digitalizing solar construction. Happy Holidays!

Streamline Solar Project Commissioning with TaskMapper

Efficient commissioning ensures optimal solar asset performance from day one. Understand key commissioning activities for utility-scale solar projects and how TaskMapper enhances efficiency at every stage.

SaaS Is Transforming Solar Asset Management

SaaS solutions are reshaping solar asset management. They drive efficiencies that lead to cost savings, sustainability, and long-term operational success.

Solar EPCs & Developers: Effortlessly Manage Project Inventory With TaskMapper

TaskMapper's inventory management module helps boost solar project efficiency and reliability with features like warehouse management, stock tracking, automated alerts, transaction workflows, and BOM.

Work Anywhere: How TaskMapper Mobile Powers Offline Field Operations

TaskMapper Mobile is an offline-first app that ensures field operations continue seamlessly in areas with no network coverage. Teams pre-load work (maps, ITPs/ITCs, tasks) and can fully complete QC inspections, capture geotagged photos, and create new tasks while offline. All data is stored locally and automatically syncs when connectivity is restored, providing instant progress updates and full data traceability within the Digital Twin.

The Handover Binder That Builds Itself — Automating ITPs, ITCs & QC Documentation

TaskMapper automates the Handover Binder by digitizing QC and commissioning records (ITPs, ITCs). Field teams use digital forms on-site, which the system uses to auto-generate PDFs using your templates and automatically file them in the correct DMS folders. Crucially, every record is linked to the Digital Twin, providing Asset Management with a complete, traceable, and ready-made as-built and QC record by COD.

Fixing Document Chaos — Bringing Version Control to Solar Construction

TaskMapper's Document Management System (DMS) establishes a Single Source of Truth for solar construction by enforcing structured version control for all design documents (IFCs, RFIs, permits). It ensures field crews only see the latest revision, digitally tracks all approvals, and links documents directly to the Digital Twin. This eliminates the use of outdated drawings, drastically reduces rework, and turns document control into a powerful quality control function.

TaskMapper: Streamline Mechanical Activities During Solar Construction

Overview of mechanical activities in solar energy project construction, including installing mounting structures to house PV panels, and how TaskMapper simplifies monitoring, updates, and reporting for EPC contractors.

Streamlining Civil Activities in Solar Project Construction With TaskMapper

Key civil activities in solar energy project construction, including road development and fencing and how TaskMapper simplifies their monitoring and reporting to enhance efficiency and tracking for EPC contractors.

TaskMapper Transforms Pre-Construction for Solar EPC Contractors

The pre-construction phase of solar projects can be complex and time-consuming. TaskMapper simplifies site surveys, land preparation, planning, progress tracking, and team collaboration to boost efficiency.

Design Meets Reality: How Automatic Redlines Catch Construction Deviations Early

TaskMapper's Automatic Redlines uses weekly drone scans and the digital twin to instantly detect construction deviations from the IFC/CAD design (e.g., pile positions, tracker alignment). It generates geospatially precise redlines that automatically convert into assignable QC items or corrective tasks. This process minimizes rework, prevents design violations, and ensures a continuously updated as-built record.

Building Solar With Certainty: End-to-End Material Traceability on Construction Sites

TaskMapper Inventory Management is a construction-ready tool for utility-scale solar, providing end-to-end material traceability from shipment to installation. It tracks materials across laydown yards, links all component movements and serial numbers to the project's Digital Twin, ensuring a continuous, accurate Bill of Materials. This specialized system eliminates shortages, replaces manual tracking, and provides auditable documentation for quality and warranty purposes.

Building the Digital Twin Before the First Pile: A Smarter Way to Commission and Handover

The Digital Twin for Solar is built by SenseHawk from the start of construction, integrating the plant's electrical and mechanical System Model with the site Map to track all construction history and QC. Commissioning is performed directly on the Twin using digital workflows tied to specific assets, resulting in the Twin automatically serving as the seamless handover package to O&M, eliminating data gaps and providing a complete, verified record for proactive asset management.

Managing the Interconnection Process for Utility-Scale Solar Projects

The interconnection process is essential in utility-scale solar development to ensure seamless integration into the electrical grid and this blog explores its intricacies and how TaskMapper simplifies it.

TaskMapper to Manage Securing Process for Right of Way for Transmission Line

TaskMapper simplifies process management for securing the right of way for transmission lines in solar projects. From assessment to acquisition, it improves land acquisition efficiency and clarity.

TaskMapper To Simplify Land Acquisition Processes for Large Solar Projects

Land acquisition involves assessing land use, transmission access, and water rights for solar project development. This blog explores how TaskMapper helps streamline process management.

From Manual Updates to Autonomous Progress: Using Drones for Construction Tracking

Solar projects are automating progress tracking using scheduled drone flights (including autonomous "drones-in-a-box") to capture imagery. Taskmapper processes this data to enable automated activity detection (e.g., pile installation) and instantly updates the P6 schedule and dashboards. This shifts field engineers from manual reporting to high-value validation and oversight, creating a continuous, data-driven construction site.

Ending the Weekly Markup: Linking Construction Updates Directly to the P6 Schedule

Taskmapper automates solar project scheduling by allowing users to import P6/MS Project files and link activities directly to spatial locations on the map and detailed field workflows. As crews log geotagged progress updates via the mobile app, the system automatically updates the master schedule in real-time, eliminating manual reconciliation and providing planners with instant, accurate, and auditable status reports.

Turning Up the Heat on Rare Thermal Signatures

Solar thermal inspections are increasingly revealing rare and unusual thermal signatures—such as unique heating patterns in bifacial and half-cut modules, or dark material-concern patches—that deviate from standard issues. These anomalies have critical, undocumented implications for system performance and reliability, requiring solar professionals to understand and address them to protect yield and warranties.

Streamline and Manage Complex Solar Project Development Workflows with TaskMapper

The project origination and development workflow is the backbone of the solar asset lifecycle. This blog explores the intricacies of the process and how TaskMapper can be a game-changer in streamlining it.

Digital Twins: Game-Changers in Solar Construction and Handover

In the solar PV sector, digital twins are predominantly associated with operational assets and maintenance. However, they can play an equally valuable role during the construction phase of solar assets.

10 Ways TaskMapper Helps Solar Project Managers During Construction

To maximize the ROI on solar PV projects, project managers need to ensure that every aspect of asset construction is completed on time, within budget, and without compromising on build quality.

Automating QC: How One EPC Digitized Their Entire Construction Workflow

An EPC client digitized their solar QC using Taskmapper, integrating imported CAD layers with linked construction workflows directly on a site map. This process automated progress tracking and embedded digital QC forms requiring geotagged photos and signatures at every step. The system automatically compiles complete, branded, and auditable QC reports, simultaneously linking progress updates to the main Project Schedule.

Why Every Solar Project Needs a Digital Twin

The Digital Twin for Solar unifies fragmented project data, acting as a single, living digital representation of a solar plant across its lifecycle. It integrates design, real-time construction monitoring (via drone data), and geotagged QC inspections into one system-of-record. This unified approach eliminates data silos, cuts rework, provides a seamless digital handover to O&M, and ultimately accelerates COD and improves plant uptime.

Building Confidence in Pile Quality

Taskmapper digitizes and streamlines solar project pile installation and QC, replacing spreadsheets with a real-time project map visualization. Automated workflows track progress, guide quality checks with required photo and signature capture, and ensure accuracy and accountability. The system automatically generates and saves the final QC report to the DMS, providing a single source of truth and eliminating manual errors.

Streamline complex construction and operations with end-to-end digitization

Project managers, contractors, and EPCs at construction companies struggle to track all project aspects, including logistics, scheduling, monitoring, and communication. Digitization is the solution.

5 Ways SenseHawk Drone Analytics Empowers Solar Asset Stakeholders

SenseHawk Drone Analytics helps extract actionable insights from solar sites to enable stakeholders to drive down costs and optimize operations.

Key Strategies for Effective Solar Project Construction Management

Discover key strategies for successful solar project construction management. Assess your current processes to identify areas to improve.

SenseHawk's New Document Management Solution: Enhancing Efficiency in Solar Projects

The new DMS system integrates eamlessly with the TaskMapper platform and is a comprehensive solution to enhance the efficiency and security of document management in solar projects. It centralizes documentation and simplifies access throughout the asset lifecycle.

Best Practices for Smooth Functioning of Solar Assets After Weather Events Like Hail and Hurricanes

Best practices in site planning, design, and operations protects solar investments from weather-related damage. In case of EWE, TaskMapper equips teams with tools for swift recovery.

Manage Solar Project Due Diligence with TaskMapper

TaskMapper helps simplify due diligence for solar projects. From legal reviews to technical assessments, it streamlines workflows, digitizes approvals, and keeps teams aligned for compliance and efficiency.

Simplified Solar Asset Work Management and Reporting with TaskMapper

TaskMapper offers an integrated solution for managing work and reporting throughout the solar asset lifecycle.

TaskMapper identifies and meets the diverse needs of solar PV stakeholders

The solar PV project lifecycle involves multiple stakeholders, and accurately meeting their needs significantly increases the value derived from the asset.

TaskMapper : GIS-powered site planning and as-built monitoring

Map-based terrain analysis and construction monitoring improves planning, collaboration, and tracking for successful execution of solar projects.

Vertical SaaS in Solar Asset Management: Revolutionizing Efficiency and Integration

Vertical SaaS solutions like TaskMapper address key challenges for solar operators, integrating functions seamlessly across project phases and providing real-time insights for smarter decision-making.

Simplify Solar Project Financial Processes with TaskMapper

Utility-scale solar project fianacing spans stages from development and due diligence to construction monitoring and loan repayment. TaskMapper streamlines collaboration and ensures compliance with lender conditions for timely loan disbursement.

Drone Analytics in Solar Construction and O&M

Drone data is transforming utility-scale solar asset management. From construction monitoring to O&M workflows, TaskMapper’s drone analytics optimizes project management using high-res maps, actionable insights, and task management.

Digital tools for solar construction in the post COVID era

Digital tools for solar construction in the post COVID era

How the SenseHawk Digitization Platform helped clients minimize project-lifecycle related obstacles and associated risks in the first 12 months of the pandemic.

Findings from 14 GW of thermography in 17 countries

Findings from 14 GW of thermography in 17 countries

Insights from drone inspections and analytics capabilities of the SenseHawk Digitization Platform at various sites across countries and technologies.

SenseHawk remediates defects at 8th largest solar powerplant

SenseHawk remediates defects at 8th largest solar powerplant

SenseHawk helps with defect identification, classification, and prioritization for faster remediation at the 8th largest solar power plant in the world at the time.

Streamline Solar Project Commissioning with TaskMapper

Efficient commissioning ensures optimal solar asset performance from day one. Understand key commissioning activities for utility-scale solar projects and how TaskMapper enhances efficiency at every stage.

SaaS Is Transforming Solar Asset Management

SaaS solutions are reshaping solar asset management. They drive efficiencies that lead to cost savings, sustainability, and long-term operational success.

Solar EPCs & Developers: Effortlessly Manage Project Inventory With TaskMapper

TaskMapper's inventory management module helps boost solar project efficiency and reliability with features like warehouse management, stock tracking, automated alerts, transaction workflows, and BOM.

In the news

TaskMapper Solar

Products

TaskMapper Solar

TaskMapper Solar

Products